One of the most rewarding parts of the Sling journey—beyond the flying itself—is diving deep into how the plane works, especially the engine. I’ve read Mike Busch’s books on aircraft engine ownership and maintenance cover to cover, and they left me with a strong sense that if you’re going to fly it, you ought to understand it—and be able to care for it.

That’s what brought me to Rotax service training.

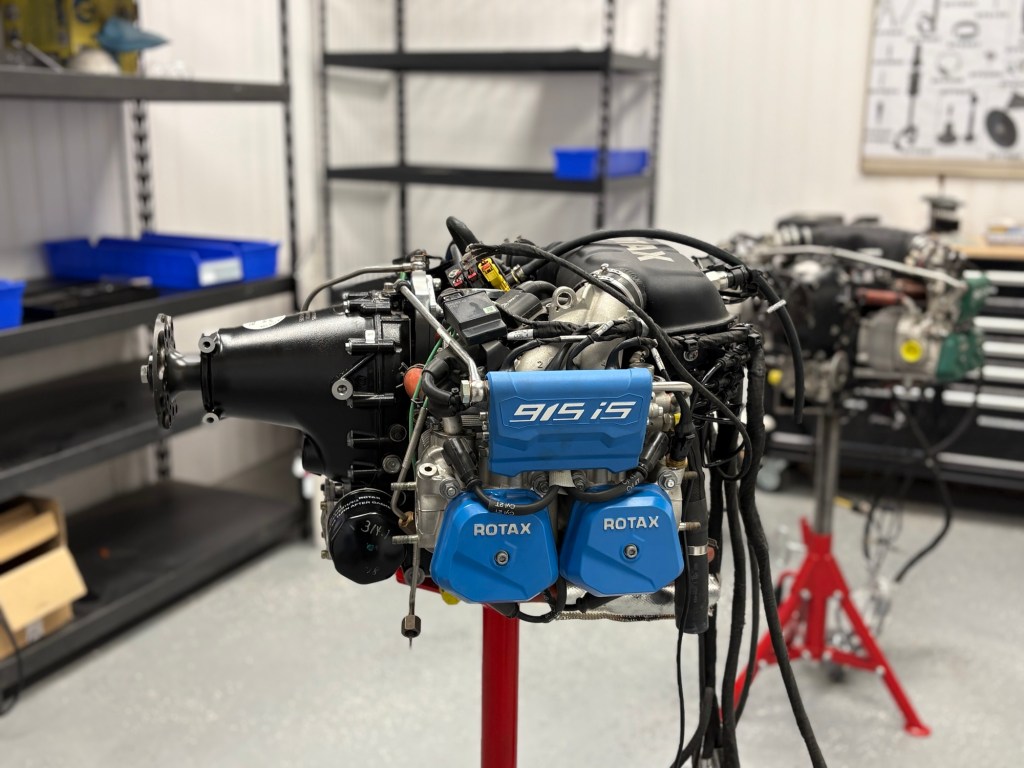

This training isn’t just about tightening bolts or changing oil. It’s a foundational course in understanding the Rotax engine’s design, operation, and required service intervals. The Rotax 916iS powering my Sling has specific service requirements at 50 hours, 100 hours, and annually—some of which overlap and some that escalate in complexity. Knowing what needs to be done, and how to do it properly, isn’t optional for a builder like me. It’s part of the job.

Since my Sling is being built as an Experimental Amateur-Built (E-AB) aircraft, I’ll be eligible for a Repairman Certificate. This special certificate, issued by the FAA, allows the original builder of an E-AB aircraft to perform and sign off on the condition inspections required every year. It’s worth noting that this certificate is unique to the person and the specific aircraft they built—it doesn’t transfer, and it doesn’t apply to other aircraft. According to the FAA:

“The repairman certificate is available to individuals who are directly involved in the construction of an amateur-built aircraft. This certificate permits the holder to perform the annual condition inspection on the aircraft that they built.” FAA Source

While I intend to take full advantage of this certificate down the line, I also know there’s a learning curve. My plan is to lean on the experts for now: I’ll use an authorized Rotax service center for the more complex maintenance tasks, and collaborate with a trusted independent Rotax A&P for the rest. Over time—probably after logging a few 50- and 100-hour services together—I hope to gain the confidence and hands-on experience to handle annual inspections myself.

Navigating the Rotax Certification Pathway

Rotax offers a structured Independent Rotax Maintenance Technician (iRMT) training program, designed to equip individuals with the knowledge and skills necessary for maintaining Rotax aircraft engines. The program comprises several courses, each targeting different levels of expertise and maintenance responsibilities:

- Familiarization Course: This introductory course is tailored for pilots, homebuilders, managers, and owners. It provides a foundational understanding of Rotax aircraft engines, covering engine systems, operation, and maintenance requirements.

- Service Course: Aimed at owners and technicians, this course delves into service and inspection procedures up to the 100-hour or annual maintenance level. It encompasses both theoretical knowledge and practical skills.

- Maintenance Course: Targeted at technicians, flying schools, OEMs, and FBOs, this course focuses on maintenance-level tasks, including the removal and replacement of engine components.

- Heavy Maintenance Course: Designed for experienced maintenance personnel, this advanced course covers in-depth topics such as engine teardown, inspection, and reassembly.

- Overhaul Course: An invite-only course for seasoned professionals, it provides comprehensive training on overhauling Rotax engines and components.

Each certification is valid for 24 months, after which a renewal course is required to stay current with the latest procedures and standards.

My Training Journey: Familiarization and Service Courses

In my pursuit to proficiently maintain my Sling aircraft, I enrolled in both the Familiarization and Service courses. These courses provided a balanced blend of theoretical knowledge and hands-on experience, aligning perfectly with my current expertise level. They equipped me with the skills necessary to perform routine maintenance tasks without compromising safety. As I gain more experience and confidence, I plan to undertake the Maintenance course to further enhance my capabilities.

The Role of the Rotax Flying and Safety Club (RFSC)

The RFSC serves as the official training organization authorized by Rotax for the Americas. It oversees the iRMT training program, ensuring standardized, high-quality instruction across various independent training centers. The RFSC’s responsibilities include:

- Curriculum Development: Designing and updating course materials to reflect the latest industry standards and Rotax engine advancements.

- Training Oversight: Monitoring and accrediting independent training centers to maintain consistent training quality.

- Certification Management: Issuing and renewing iRMT certifications, ensuring technicians remain up-to-date with current maintenance practices.

By centralizing these functions, the RFSC plays a crucial role in maintaining the integrity and effectiveness of the Rotax maintenance training ecosystem.

Training at Motive Aero: Hands-On Learning in the Heart of the Desert

For my Rotax service training, I chose to attend Motive Aero’s headquarters in Hurricane, Utah. While they offer courses across the western United States, including locations like Torrance, CA, and Petaluma, CA, I opted for their home base because the timing worked with my schedule. Motive Aero is an official BRP-Rotax Service Center, providing parts, service, and support for Rotax aircraft engines throughout the Western United States.

The training facility is situated at Hurricane Municipal Airport (1L8), also known as General Dick Stout Field. This public airport, owned by the City of Hurricane, features a single asphalt runway (01/19) measuring 3,282 feet in length. Located approximately three miles south of the town center, the airport sits at an elevation of 3,351 feet MSL.

Hurricane itself is a charming city nestled in southwestern Utah, serving as a gateway to the stunning landscapes of Zion National Park. The area is renowned for its red rock formations, outdoor recreational opportunities, and a welcoming community.

Our instructor, Michael Burton, is the owner of Motive Aero and has an uncanny depth of knowledge when it comes to Rotax engines. His approach to training is straightforward and focused, making even the more complex aspects of engine service approachable and clear.

Classroom Training: Building the Foundation

The classroom portion of the Rotax training served as the foundational piece of the course—designed to give students a working understanding of how Rotax engines function, their unique systems, and the philosophy behind their design. Led by Michael Burton, this day focused on laying the theoretical groundwork required for safe operation and effective service of Rotax engines, particularly in experimental and light-sport aircraft.

Course Structure

The curriculum was based primarily on the Familiarization Course, with some introductory material from the Service Course. It was structured around core systems in the engine and included technical background, operational principles, and maintenance intervals. The classroom sessions were interactive, with real-world examples, Q&A, and plenty of side notes from Michael’s own experience.

Key Topics Covered

- Rotax Philosophy & Certification Rotax’s focus on lightweight, modular designs.

- The reasoning behind overhaul vs. replace decisions. Overview of engine variants and certification tags.

- Engine Systems Overview Oil System: Dry sump design, burping/purging procedures, tank function, oil change intervals, and issues related to air in the lines.

- Cooling System: Water-cooled heads, air-cooled cylinders, emergency operation limits, and coolant types.

- Gearbox: Reduction gear design, clutch system, inspection intervals, and torque testing methods.

- Ignition & Electronics: Differences between CDI and ECU systems, sensor operation, and fault handling.

- Engine Management Detailed comparison between carbureted and fuel-injected models (iS series), including the benefits of fuel savings and engine efficiency.

- ECU specifics, costs, and why it’s both robust and expensive.

- Manuals & Documentation Introduction to the core documentation sets: Installation, Operator, Maintenance (Line & Heavy), Parts Catalogs, and Service Bulletins.

- How to identify the correct documents for inspections, troubleshooting, or upgrades.

- Maintenance Planning Recommended oil, spark plugs, and inspection intervals for each engine type.

- Use of tools like the Rotax Configurator and RS Flight Systems for planning builds and selecting components.

There was significant emphasis on real-world issues: how to recognize problems early, the importance of proper oil selection (especially for the 916iS), and how to interact with service bulletins and the Rotax support ecosystem. The tone was practical and often skeptical of “old-school” maintenance mindsets—encouraging modern, data-informed approaches.

Annual Inspection Live: A Day in the Rotax Shop

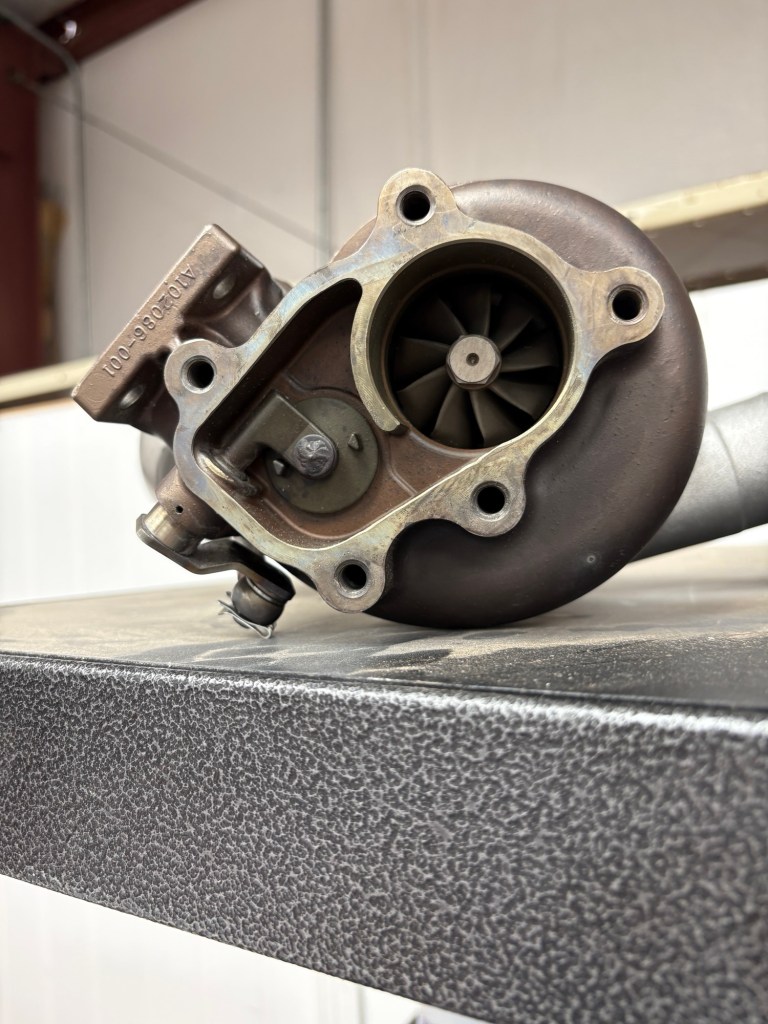

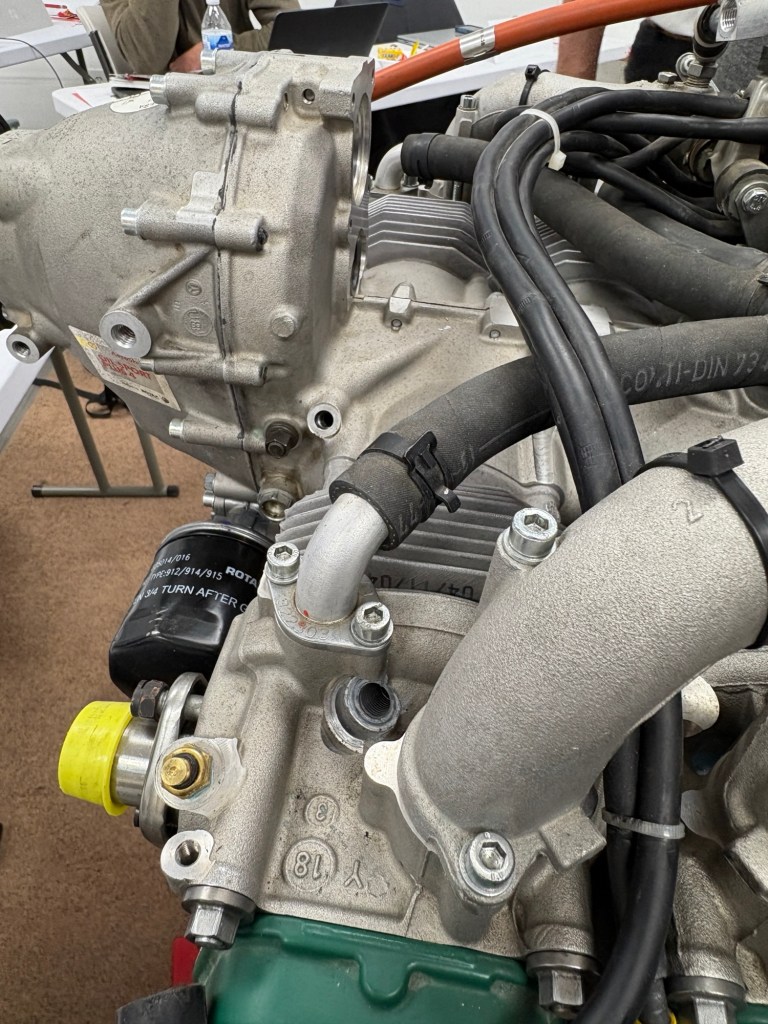

Day two of the training took us straight into the shop—where we put theory into action on a real customer aircraft: a Cavalon gyroplane powered by a Rotax 914 UL engine. This ultralight, tandem-seat gyroplane is known for its stability, efficiency, and sleek design. The aircraft was in the shop for its annual condition inspection, giving us the perfect opportunity to work through a real-world service scenario.

Following the Maintenance Manual Line (MML) procedures, we completed several standard inspection tasks:

- Cylinder Compression Test: We checked each cylinder’s ability to hold pressure, a key indicator of internal engine health. Good compression means good sealing in the combustion chamber—essential for performance and reliability.

- Oil Change: We drained the old oil, replaced the filter, and refilled with fresh oil, making sure everything was buttoned up correctly for continued operation.

- Magnetic Plug Inspection: This plug collects fine metallic particles that circulate in the oil. It’s a simple but critical early warning system—any abnormal buildup can indicate internal wear or damage.

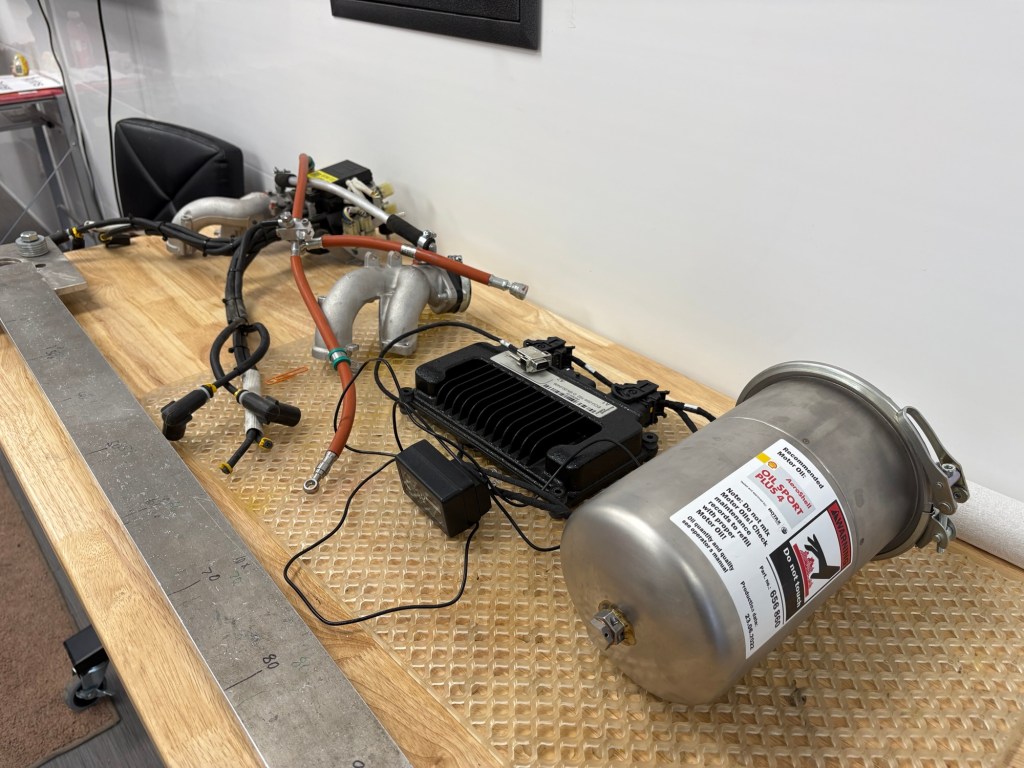

- Oil Filter Inspection: After removal, we cut open the old filter and spread out the paper element to inspect for residue or metal particles—an essential diagnostic step. ECU Diagnostics: Using a PC and Rotax interface dongle, we downloaded fault codes and engine performance data from the ECU. It’s a quick window into the engine’s digital brain—helping identify any issues that aren’t visible to the naked eye.

It was a rewarding day that grounded the theory from Day 1 in real-world application. I’ll be adding photos to this section showing each step in detail.

The Test: Navigating the Docs, Not Just the Engine

At the end of the training, we were given a 25-question open book test—not designed to trick us, but to make sure we could find our way through the Rotax documentation jungle. The focus wasn’t on memorizing facts, but on building the skill of locating accurate, serviceable information quickly.

We used a variety of official sources to answer the questions, including the Maintenance Manual Line (MML), Maintenance Manual Heavy (MMH), Operating Manual (OM), and other service documents available through the Rotax technical documentation website. These are the same resources we’ll be relying on as aircraft owners and maintainers, whether we’re performing a 50-hour service, annual inspection, or responding to a service bulletin.

One of the key takeaways was how to correctly document service work in the aircraft and engine logbooks. That means referencing the proper manuals, using the correct terminology, and ensuring that each entry is traceable and compliant. It’s not just paperwork—it’s a part of the safety chain.

To receive certification, a passing score of 75% or higher is required. A few questions were worded in a way that could trip you up if you weren’t paying close attention, but we were able to review those together in class. That review session helped tie everything together and gave me a much better grasp of how the documentation, maintenance schedules, service bulletins, and logbook entries all fit into the big picture.

Do You Need This Training? Absolutely.

If you’re planning to work on a Rotax engine—whether you’re an A&P, a builder, or just a very hands-on owner—this training is essential. While it’s not legally required in the experimental world, where the repairman certificate allows you to maintain and inspect the specific aircraft you built, Rotax has its own standards. And they matter.

For starters, Rotax only sells certain specialized tools to certified mechanics, and these tools are required for many routine maintenance procedures. More importantly, Rotax won’t honor warranty claims unless the work was done by someone who’s properly trained and certified. That makes the iRMT certification less of a “nice-to-have” and more of a practical necessity if you plan to maintain the engine yourself—or even just supervise the work being done.

I’m happy to say I passed the test and am now certified for the next two years to perform service on my 916iS engine. My plan is to approach this with care, humility, and mentorship—starting with the basics: 50-hour, 100-hour, and annual condition inspections. This training didn’t just give me a certificate—it gave me the confidence to be an informed and responsible caretaker of the engine that powers my plane.

Leave a comment