TL;DR: The Sling TSi uses push‑pull rods for ailerons, elevator, and flaps, and steel cables for the rudder. This hybrid setup delivers crisp pitch and roll control while keeping the rudder light and easy to route. It needs less frequent adjustment than all‑cable systems but still requires careful inspection of rod ends, bearings, and cable tension.

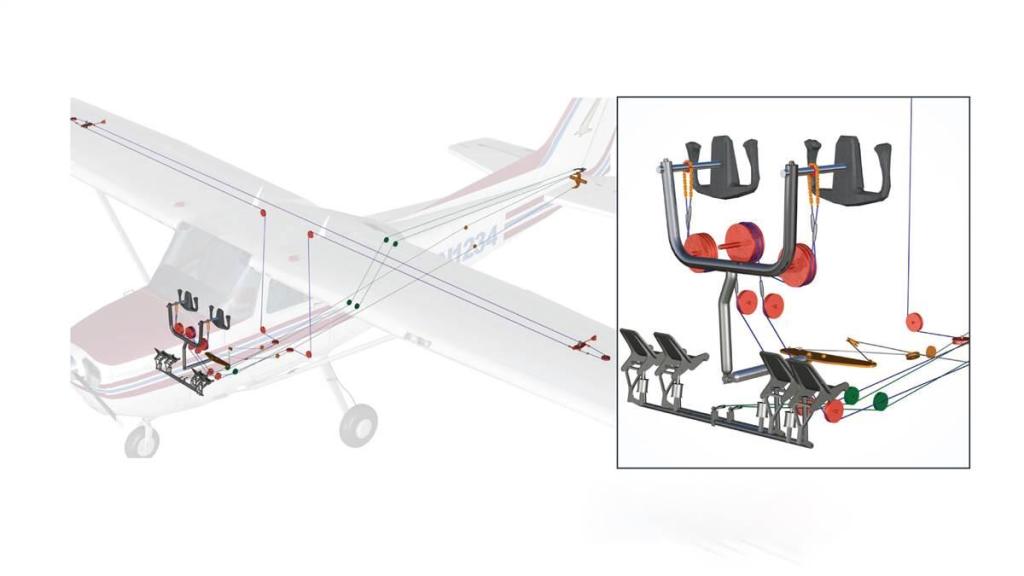

One of the first things I noticed when digging into the Sling TSi’s design is that it doesn’t stick to just one way of moving its control surfaces. The ailerons, elevator, and flaps are all actuated by rigid push‑pull rods connected through bellcranks and sealed bearings. The rudder, on the other hand, is old‑school: braided steel cables routed aft through pulleys and turnbuckles, with springs to help center it.

This hybrid approach isn’t unique to the Sling—it’s actually common in many modern experimental and certified aircraft. The Van’s RV series uses push rods for pitch and roll but cables for yaw. The Cirrus SR20/22 follows the same formula. Even the “cable-heavy” Cessna and Piper models often have short push‑rod runs between bellcranks and control surfaces (AOPA: How It Works).

So why mix and match? According to MechHead’s “Principles of Aircraft Control Systems”, the choice often comes down to routing complexity, weight, and the desired control feel:

- Push‑rod linkages provide direct, low‑stretch control—ideal for shorter, straighter runs where stiffness matters.

- Cable systems are lighter and easier to snake through tight fuselage spaces, but they need regular tensioning and are more susceptible to stretch and wear (Aircraft Systems Tech – Aircraft Rigging).

The Sling TSi fits neatly into this modern category—push rods where stiffness and precision are a priority, cables where light weight and routing flexibility make more sense.

How the Sling TSi Compares to Other GA Aircraft

| Aircraft Model | Ailerons | Elevator | Rudder | Notes |

|---|---|---|---|---|

| Sling TSi | Push‑pull rods | Push‑pull rods | Steel cables | Flaps also use push‑pull rods; mirrors RV/Cirrus layout |

| Cessna 172/182 | Steel cables (short push‑rod to surface) | Steel cables (short push‑rod to surface) | Steel cables | Classic cable‑dominant routing via pulleys |

| Piper PA‑28 | Steel cables | Steel cables | Steel cables | Cable‑dominant; long routing runs through fuselage |

| Mooney M20 | Push‑pull rods | Push‑pull rods | Steel cables | Noted for precise handling in pitch/roll |

| Diamond DA40 | Push‑pull rods | Push‑pull rods | Steel cables | Center stick control; praised for crisp feel |

| Van’s RV Series | Push‑pull rods | Push‑pull rods | Steel cables | Popular experimental kit; “on‑rails” control feel |

| Cirrus SR20/22 | Push‑pull rods | Push‑pull rods | Steel cables | Side‑yoke control; low‑friction pitch/roll feel |

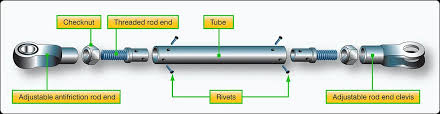

Anatomy of a Push Rod

A push rod is a rigid tube—usually aluminum or steel—that transmits control inputs by pushing or pulling on the control surface.

Key parts:

- Tube or shaft – The main structural element.

- Rod ends (heim joints) – Spherical bearings at each end, allowing for rotation and slight misalignment.

- Jam nuts – Lock the rod end in place after adjustment.

- Hardware fittings – Bolts, washers, and safety wire attaching the rod to bellcranks or control horns.

Push rods don’t stretch like cables, which helps preserve control precision, but rod ends can wear and corrosion is a concern—especially in humid or coastal environments.

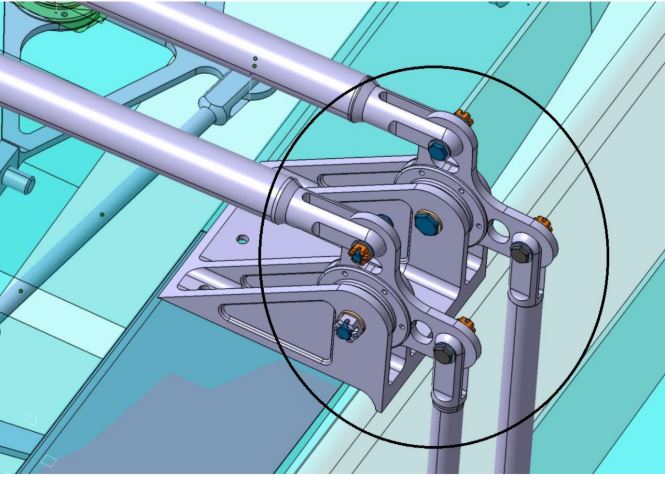

What’s a Bellcrank?

A bellcrank is a pivoting lever that changes the direction of motion of a push rod control assembly. In the Sling TSi:

- A push rod from the control stick might connect to a bellcrank in the fuselage.

- The bellcrank pivots and transfers motion into another push rod toward the control surface.

- This allows routing around structure while keeping the linkage rigid and direct.

Push Rod vs. Cable – Trade‑Offs

| Feature | Push Rods | Cables |

|---|---|---|

| Control feel | Crisp, direct, minimal play | Slight elasticity gives a softer feel |

| Weight | Heavier over long runs | Lighter for long runs |

| Routing | Needs straight or gently curved paths | Flexible routing around tight spaces |

| Maintenance | Inspect rod ends, bearings, jam nuts; watch for corrosion | Inspect for fraying, pulley wear, corrosion; check and adjust tension |

| Adjustment frequency | Rare, unless components replaced | Regular tension checks and adjustments |

| Common failure modes | Worn rod ends, corrosion | Frayed strands, seized pulleys, misrigging |

| Rigging risk | Alignment errors possible, less frequent | Misrigging can cause reversed controls |

Inside the Sling TSi’s Control Systems

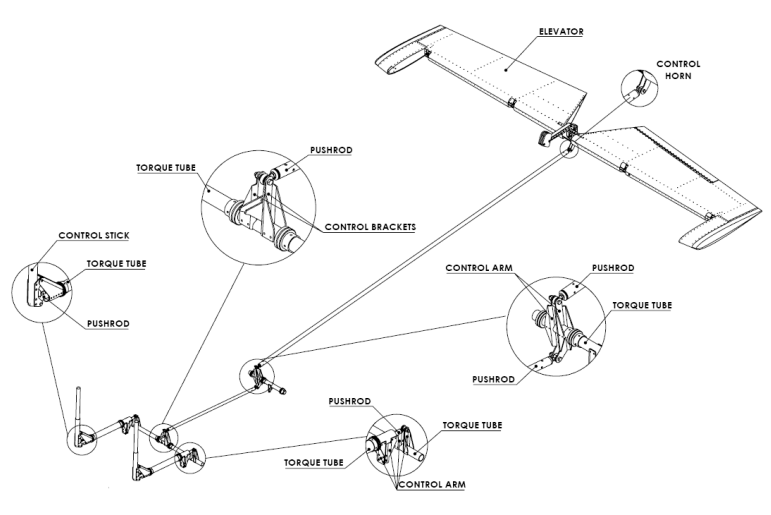

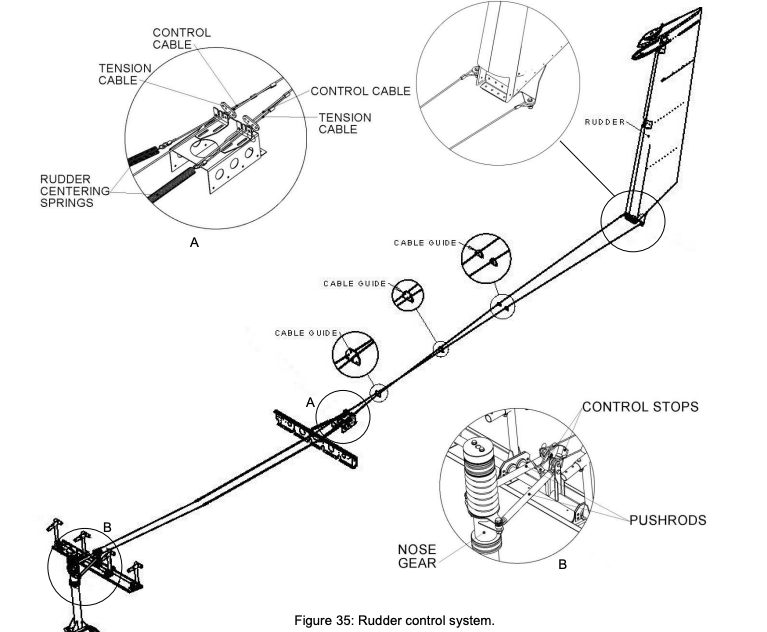

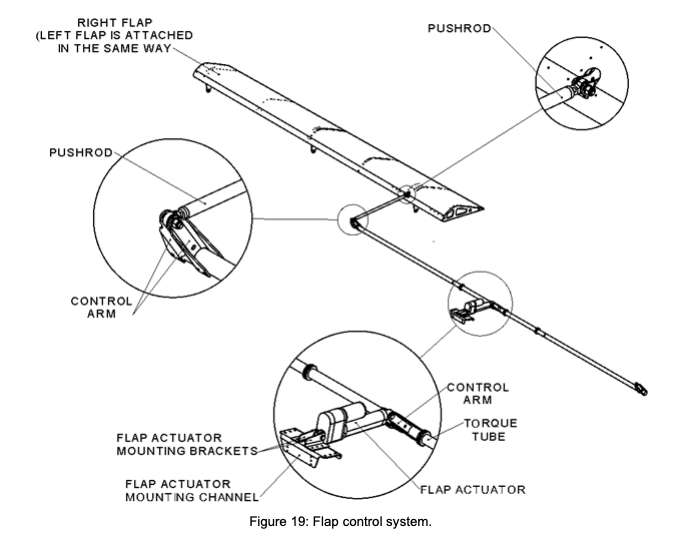

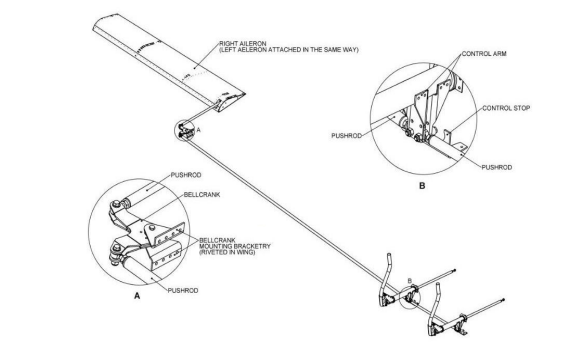

The Sling TSi’s control architecture is a study in purposeful design, blending rigid push‑rod linkages with traditional cable runs where each works best. All images source is the Sling TSi Maintenance Manual Rev 1.3.

Elevator System – Controlled via a series of push rods and torque tubes running from the control stick to the tail. Bellcranks and control arms redirect motion while keeping the linkage rigid for precise pitch control.

Rudder System – Operated through braided steel cables routed via guides and pulleys to the rudder horn. Tension cables and centering springs ensure smooth, balanced yaw response.

Aileron System – Uses push rods from the control stick to in‑wing bellcranks, then out to the aileron control arms. This minimizes play and gives the Sling its signature roll precision.

Flap System – Electrically actuated, with torque tubes and push rods transferring motion from the central flap actuator to each flap control arm.

The diagrams make it clear how the Sling’s designers optimized for both control feel and maintainability—keeping most linkages rigid and direct, while routing the rudder through cables to simplify the path through the fuselage.

Maintenance Best Practices for the Sling TSi

Push Rods

- Inspect rod ends for play, corrosion, or binding.

- Check jam nuts for tightness and proper safety wiring.

- Look for corrosion, especially in steel tubes; clean and repaint if needed.

- Lubricate rod ends lightly to avoid grit buildup.

- Inspect bellcranks for smooth pivoting and good bushing condition.

Cables

- Check tension per Sling’s maintenance schedule.

- Inspect for fraying—replace if even one strand is broken.

- Ensure pulleys rotate freely and grooves are free of sharp edges.

- Lubricate only where specified.

- After maintenance, verify correct routing and freedom of movement.

Why This Matters to Pilots

The Sling’s hybrid system isn’t just an engineering decision—it shapes how the airplane feels and performs. Push rods give you that “on rails” precision in pitch and roll, perfect for IFR tracking and crosswind finesse. The cable rudder keeps weight down and routing simple, while still delivering solid yaw control.

For pilots coming from cable‑dominant designs, the Sling’s control feel is an upgrade—responsive, predictable, and confidence‑inspiring. For owners, knowing the strengths and maintenance needs of both systems is key to keeping that feel for years to come.

Sources

- Sources (with links)

- Sling TSi Maintenance Manual

- Principles of Aircraft Control Systems – MechHead.com

- Aircraft Rigging – AircraftSystemsTech.com

- How It Works – AOPA Flight Training Magazine

- Diamond DA20 AFM – Diamond Aircraft

- DA40 General Description – Propwash.yolasite.com

- VansAirForce.net – Push Rod vs Cable forum threads

- SlingPilots.com – Owner feedback threads

- MooneySpace.com – Push Rod corrosion discussion

- FAA AC 43.13‑1B – Aircraft Inspection & Repair

Leave a comment