I’ve been talking about building my Sling TSi for months. I’ve picked avionics, argued with myself over propellers, and researched boost pumps at 1 am. Now, finally, the day is almost here—on August 18th, the build officially begins at The Airplane Factory in Torrance, California.

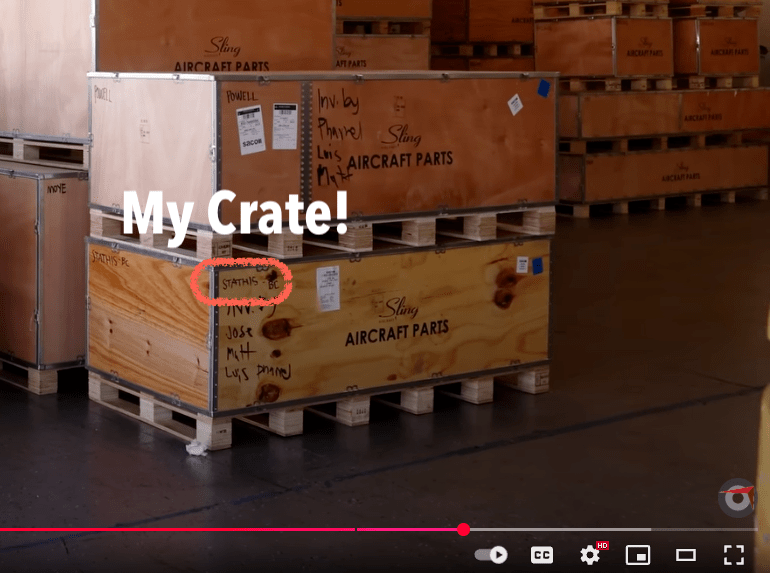

And here’s a little twist I didn’t expect: my airplane kit has already made its YouTube debut. Over the weekend, the Pilot’s Academy channel posted a factory tour video, and in a few quick shots—there it was. Crates stacked neatly, with my name on them, waiting their turn on the factory floor.

You can watch the video below (I’ll even save you the trouble of pausing and squinting—I’ve included a screenshot at the top of the post so you can spot the “celebrity crate” moment).

Over the next few months, this blog will turn into a front-row seat to the build process. I won’t be posting “Monday we did this, Tuesday we did that.” Instead, each post will be built (pun intended) around one major part or system—wings, fuselage, empennage, landing gear, controls, avionics—and will include:

- Details of the part or component under construction

- Timeline of progress as it comes together

- Work & tools used, challenges faced, and decisions made

- Photos & videos from the factory floor

- Insights & lessons learned for future builders

What I Know So Far

The factory’s latest update to me was short and sweet:

“We are planning on getting your fuselage up on the landing gear and getting the engine hung at the beginning of the week of August 18 and starting work on your wings and empennage the week of August 25 or September 1.”

That’s it—just enough to start booking flights and dusting off my safety glasses.

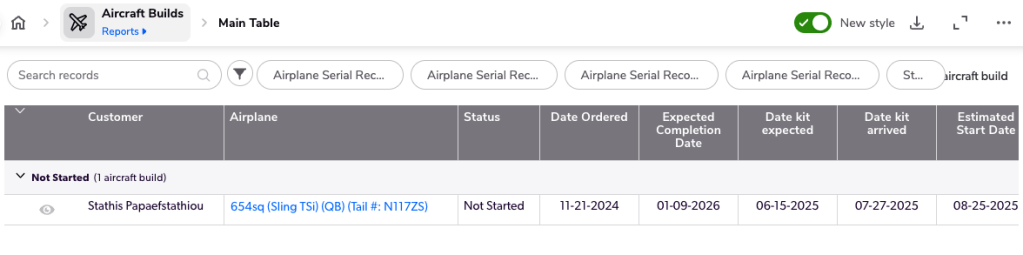

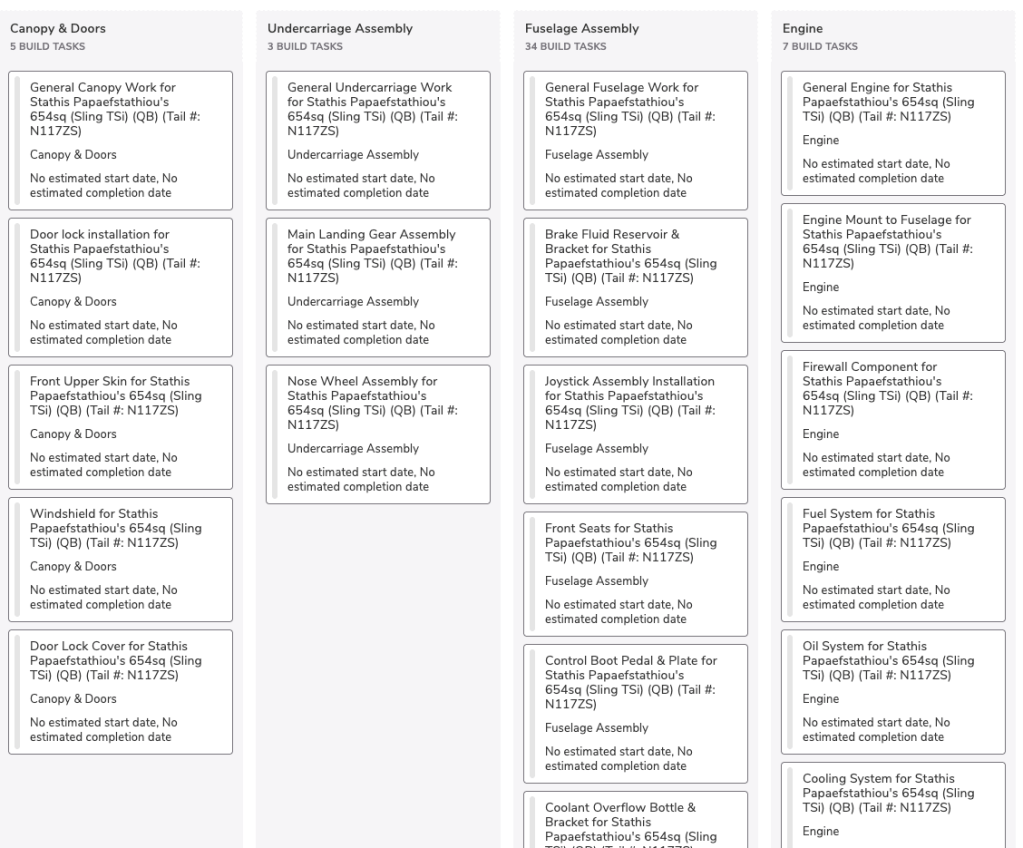

Getting Plugged Into SlingShot

This week I registered for SlingShot, The Airplane Factory’s build tracking system created on the Quickbase platform. It’s basically the builder’s mission control:

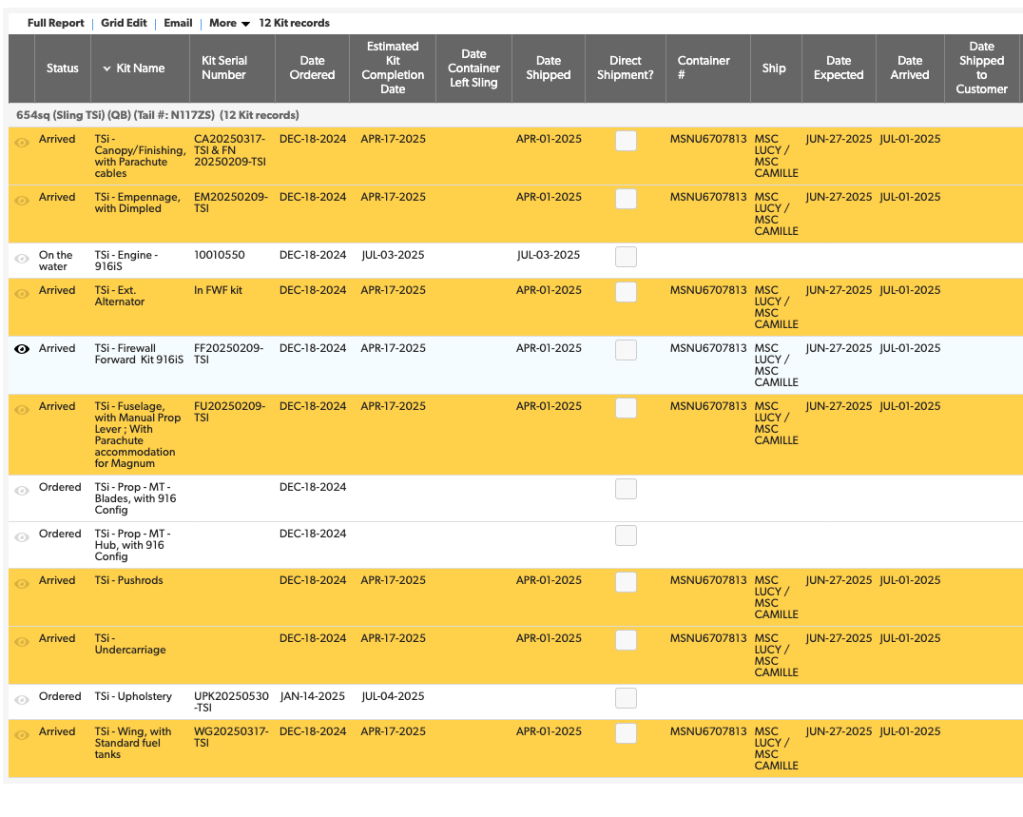

- A parts tracker with the order and delivery status for every nut, bolt, and major assembly

- A Kanban-style board showing each step of the build

- Access to the latest build manuals

- And eventually, a one-stop shop for ordering parts post-build

Most of my parts are already on site, but a few heavy hitters are still on the way:

- Rotax 916iS engine

- MT propeller (for now—see below)

- Upholstery

I’ll find out more about what’s actually in the hangar and what’s still in transit during my first visit next week.

The Open Items (a.k.a. The Fun Debates)

Two big decisions still need to be nailed down:

- Propeller – The plan right now is an MT hydraulic constant-speed propeller, but I’ve got a strong preference for the Airmaster electric constant-speed propeller. Here’s why.

- Boost pumps – I’m considering adding auxiliary boost pumps to reduce the risk of vapor lock. More on that here.

These will be top of the list when I meet with the factory team in person.

Wrapping Up

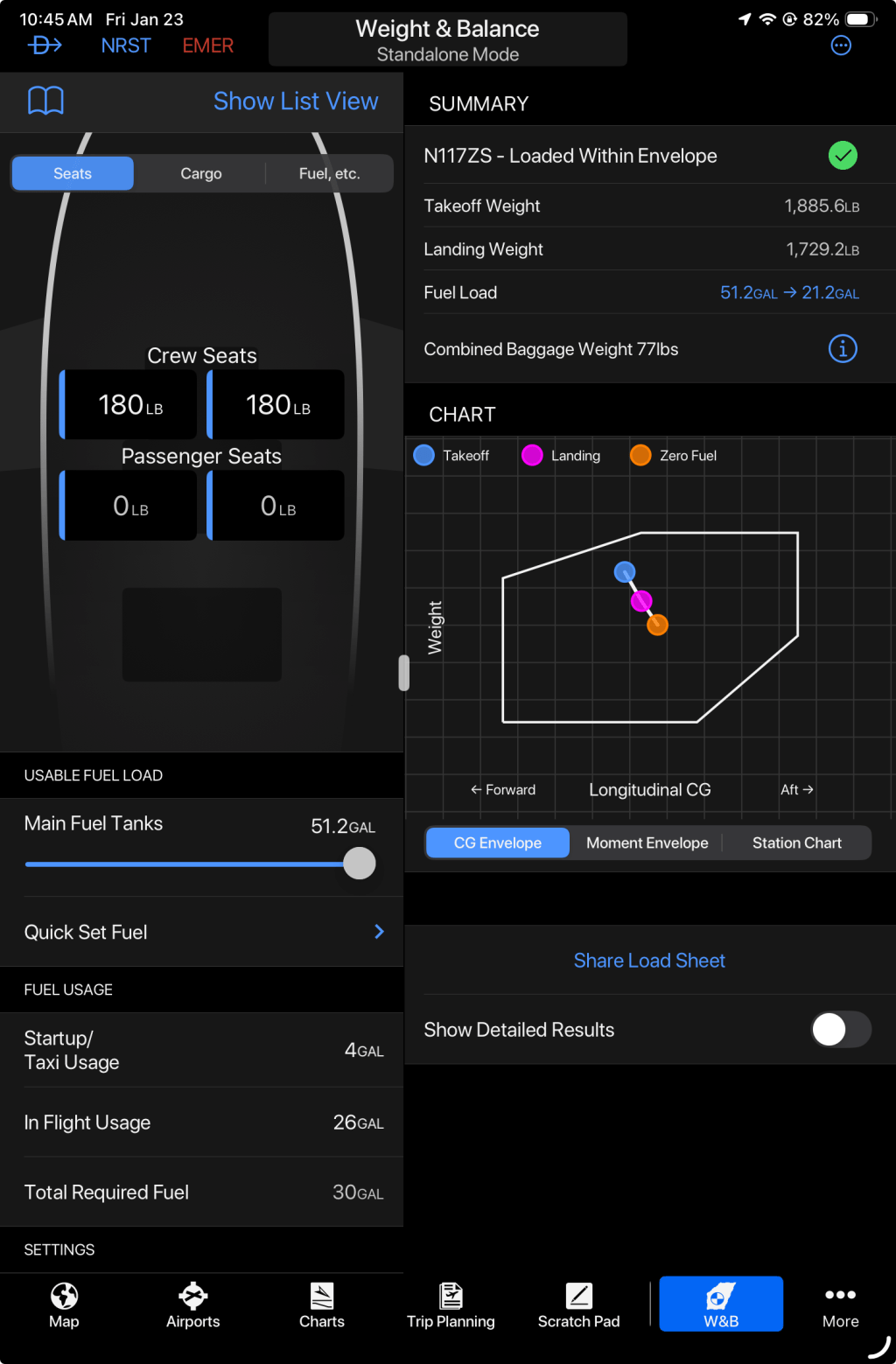

In just a few days, N117ZS will begin its transformation from a collection of crates (some of which are already YouTube famous) into a flying airplane. It’s the start of a chapter I’ve been anticipating for a long time, and I’m looking forward to sharing the highs, the challenges, and the lessons learned along the way.

Whether you’re here as a DAR (Designated Airworthiness Representative) keeping tabs on 51% compliance, a fellow builder curious about the factory assist program, or a friend or family member cheering from the sidelines—thanks for following along. Your encouragement and interest mean a lot.

Next stop: Torrance, rivet gun in hand, camera ready. Let’s build an airplane.

Leave a comment