TL;DR: Rotax’s iS-series engines were built for unleaded fuel, not 100LL. MOGAS keeps them cleaner and cheaper to maintain, but avgas is still what most U.S. airports pump. The smart move is to use MOGAS whenever possible and 100LL when you must—add Decalin, use semi-synthetic oil, and stick to 50-hour oil changes. Mixing a bit of 100LL with MOGAS can also reduce vapor-lock risk in hot weather. Performance is identical; the real difference is maintenance and cost. With the FAA aiming to phase out leaded avgas by 2030, the future is already on Rotax’s side.

If you fly behind a Rotax 916iS (or any of the Rotax family engines), one of the first practical questions you’ll face it’s what kind of fuel to put in the tank.

Rotax tells you right up front: these engines prefer unleaded fuel. In fact, they were designed from day one to sip premium auto gas (MOGAS), not the 100LL avgas that’s been the lifeblood of general aviation for decades. But step onto almost any airport ramp in the U.S., and what do you see? That same familiar blue pump, proudly dispensing leaded avgas like it’s still 1978.

So now you’ve got a dilemma. You know MOGAS keeps your Rotax cleaner, cooler, and cheaper to maintain—but it’s rarely available on the field. Meanwhile, 100LL is everywhere, but brings the baggage of lead deposits, shorter oil intervals, and higher costs.

It’s the aviation equivalent of being told to “eat vegetables” while your only nearby restaurant is a burger joint.

This post breaks down the real-world trade-offs between MOGAS and 100LL for Rotax iS engines—from maintenance and performance to practicality and future fuels. It’s based on the detailed paper linked below, condensed into something you can actually read on a coffee break (without needing a degree in chemistry).

By the end, you’ll know not just what Rotax recommends, but how to make it work in the U.S.—where unleaded fuel is still more wish than reality.

This is a great video that provides an overview of the tradeoffs between AVGAS and MOGAS in aviation.

What the Rotax Manual Really Says

Let’s skip the rumors and go straight to the official word from Rotax. The company spells out fuel requirements in Service Instruction Selection of Suitable Operating Fluids for ROTAX, Engine Type 91X i (Series), which covers all the modern fuel-injected Rotax engines—the 912iS, 915iS, and 916iS.

According to that document, your engine may burn two types of fuel:

- Unleaded automotive gasoline (MOGAS) that meets EN 228 or ASTM D4814 specifications, with up to 10 % ethanol (E10), and an octane rating of at least 91 AKI / 95 RON.

- AVGAS 100LL, the blue avgas that dominates U.S. airports.

Here’s the key line straight from Rotax:

“AVGAS is rated by MON values. AVGAS 100LL has a high lead content and forms deposits in the combustion chamber and piston rings as well as lead sediments in the oil system. However AVGAS is approved for use and it is beneficial in cases of problems with long storage periods, vapor lock or when other types of fuels are not available. Altitude and ambient temperature should also be considered when selecting AVGAS fuel to help prevent a vapor lock scenario.

— Rotax SI-916 i-001R6 Rev. 02, 2024

That sentence says it all. You can run 100LL safely—but if you do it all the time, you’ll pay for it with extra maintenance. Lead in avgas contaminates oil, fouls spark plugs, and leaves residue in the gearbox and valves. Rotax’s guidance is clear: if more than about 30 % of your total fuel use is 100LL, you need to shorten your oil-change and inspection cycles.

By contrast, unleaded premium MOGAS is what these engines were built around. It burns cleaner, keeps the internals free of lead sludge, and allows the full 100-hour oil-change interval that Rotax intended.

The Maintenance Reality

If you want to understand why Rotax keeps nudging pilots toward unleaded fuel, look no further than your maintenance logbook. The difference between MOGAS and 100LL isn’t just philosophical—it’s mechanical, and it shows up every 25 to 100 hours.

When you burn unleaded MOGAS, your engine oil stays remarkably clean, your spark plugs don’t look like they’ve been dipped in chalk dust, and the gearbox can go its full 1,000-hour inspection interval without complaint. But switch to 100LL, and you start fighting the invisible creep of lead everywhere it doesn’t belong.

Here’s what changes when you live on the blue stuff:

Oil and Filter

Rotax allows 100-hour oil changes on unleaded fuel. But if you use 100LL—even part of the time—the recommendation drops to 50 hours, and many mechanics advise 25 hours if avgas is your main diet. Why? Because lead from the fuel ends up as microscopic sludge in your oil system. Over time, that sludge collects in the oil tank, lines, and gearbox.

Also, if you burn 100LL, you can’t use a fully synthetic oil. Synthetic blends can’t suspend lead properly. Rotax specifically calls for mineral or semi-synthetic oil such as AeroShell Sport Plus 4 when any avgas is in the mix. With pure unleaded fuel, you’re free to use a full synthetic and enjoy those longer intervals.

Spark Plugs

Lead and spark plugs are not friends. When you run on 100LL, the plugs foul faster—often within 50 hours—developing the signature gray crust of lead oxides. The official Rotax schedule calls for plug inspection or replacement every 200 hours on leaded fuel versus 400 hours on unleaded. Most owners running 100LL simply clean or swap them every oil change to keep mag checks smooth.

Gearbox and Deposits

The gearbox on a Rotax isn’t just a bunch of gears—it includes a slipper clutch designed to protect against prop strikes and torsional loads. Unfortunately, lead also likes to hang out there. On a steady diet of 100LL, the gearbox inspection interval drops from 1,000 hours to 600 hours. The same lead buildup that fouls plugs can stick valves, affect compression, and shorten the time between top-end overhauls.

Cleaning and Inspections

If you run mostly avgas, expect some extra housekeeping. The oil tank occasionally needs to be cleaned of lead sludge, and you may find yourself de-carbonizing valves or inspecting deposits sooner than the official TBO suggests.

In contrast, a Rotax that runs mainly on unleaded fuel looks startlingly clean inside. Mechanics describe teardown engines after 1,000+ hours on MOGAS as “almost new.”

Bottom line:

Running on MOGAS doesn’t just save you money—it saves your weekends. Fewer oil changes, cleaner plugs, longer gearbox life. 100LL works fine, but it turns your maintenance schedule into a short story instead of a novel.

Reliability and Longevity

Every Rotax owner eventually asks the same question: Will my engine last as long if I run 100LL?

The short answer: yes—if you’re willing to babysit it. The long answer: unleaded fuel makes that job a whole lot easier.

Engines that live on unleaded MOGAS tend to reach their 2,000-hour TBO with surprisingly few surprises. When torn down, they show clean valves, shiny piston crowns, and compression numbers that make mechanics smile. The same engines run primarily on 100LL often tell a different story—sticky valves, gray deposits, and more frequent top-end work to keep performance in spec.

Lead is the villain here. It doesn’t just foul plugs; it sneaks into valve guides, forms crusty buildup in combustion chambers, and slowly steals compression. It also contaminates the oil, which increases wear unless you change it religiously.

A few data points from the real world:

- Owners who run mostly MOGAS report engines going well beyond 2,000 hours before overhaul with minimal internal wear.

- Pilots who stick to 100LL can still get excellent reliability—provided they keep up with 25- to 50-hour oil changes, frequent plug cleaning, and gearbox inspections at 600 hours instead of 1,000.

- Flight schools that switched their fleets from 100LL to unleaded UL94 reported immediate benefits: cleaner plugs, smoother idles, and fewer rough-running issues after cold starts.

To Rotax’s credit, these engines are remarkably tolerant. They’ll run on 100LL all day if you treat them right; they’ll just make you work for that reliability.

In contrast, an engine burning MOGAS doesn’t need coddling. It stays cleaner by design. Less lead means fewer reasons for anything to stick, slip, or seize.

Bottom line:

A Rotax iS engine will run happily on either fuel—but it will age more gracefully on unleaded. Think of 100LL as junk food: fine in moderation, but don’t make it your daily diet if you want a long, healthy engine life.

Performance and Operational Differences

If you’re expecting a big performance swing between MOGAS and 100LL, you’ll be disappointed—or relieved. The Rotax iS engines don’t care much about the color of the fuel, as long as it meets the octane spec. Both fuels deliver full power, smooth operation, and identical climb performance.

That said, there are a few small operational quirks worth knowing about.

Power and Octane

Rotax specifies 91 AKI (95 RON) or higher, so both premium pump gas and 100LL easily clear the bar. Running higher octane (say, 93 AKI) won’t give you more power—it just adds a little extra detonation margin, which is nice for turbocharged 915iS and 916iS engines running at high manifold pressures.

In other words: both fuels make the same horsepower; one just costs more and leaves a little gray dust behind.

Fuel Energy Content

Ethanol-blended MOGAS (E10) contains slightly less energy—about 3% less per gallon than pure gasoline. In practice, that means a tiny difference in range or fuel flow. You might burn an extra tenth of a gallon per hour, but you’ll never notice it in cruise.

Vapor Lock and Hot Conditions

This is where fuel choice can matter. MOGAS—especially summer-blend automotive fuel—has a higher Reid Vapor Pressure (RVP) than avgas, which means it’s more likely to vaporize in hot or high-altitude conditions. In older carbureted Rotaxes, that could lead to vapor lock.

The good news? The fuel-injected iS engines (912iS, 915iS, 916iS) are much less susceptible because their systems keep fuel under constant pressure—around 43 psi—with a return line that keeps it cool and circulating. Still, on sweltering days or after heat soak, a touch of avgas or a boost pump can provide peace of mind.

In fact, many experienced Rotax owners have found that mixing a small amount of 100LL with MOGAS—say 10–25%—can dramatically reduce vapor lock risk. The avgas lowers the overall vapor pressure of the blend, while the mogas keeps lead content (and the resulting maintenance) to a minimum. This “cocktail” approach is a popular workaround in places where ethanol-free auto fuel has high volatility or where summer heat pushes the limits of pure MOGAS.

Engine Temps and Combustion

Some pilots report slightly higher EGTs on MOGAS, but the difference is negligible and well within limits. Both fuels detonate cleanly, and the iS-series ECU automatically adjusts mixture for any minor density changes. You’ll never need to lean or tweak anything—these engines handle that for you.

Starting and Idling

Cold starts can actually be easier on MOGAS, thanks to its higher volatility. Conversely, 100LL’s lower volatility can make extremely cold starts a bit more sluggish. At idle, unleaded fuel tends to burn cleaner and smoother over time because it doesn’t accumulate lead on plug electrodes or valve faces.

Storage and Shelf Life

If your airplane sits for long stretches, avgas has an advantage: 100LL can be stored safely for a year or more. MOGAS, on the other hand, can start to lose octane or form gums after a few months unless stabilized. For that reason, some owners fill their tanks with avgas during winter layups to avoid varnish or water absorption issues.

Bottom line:

Performance-wise, you won’t feel a difference between fuels—but you might notice the subtleties. MOGAS gives you cleaner plugs and smoother idle; 100LL gives you vapor-lock immunity and longer storage life. And if you blend them smartly, you can often get the best of both worlds: clean running, no vapor lock, and fewer lead headaches.

Availability, Cost, and Storage

Even if MOGAS is the clear technical winner for your Rotax, there’s one giant logistical problem: you can’t buy it at most airports.

In North America, 100LL is everywhere. You can pull up to a self-serve pump almost anywhere in the country, swipe your card, and go. MOGAS, on the other hand, usually means you’re rolling up to a local gas station with a few red jerry cans in the back of a truck—assuming your airport even allows it.

It’s the classic convenience-versus-cleanliness trade-off.

Availability

If you’re based at a smaller field, you might get lucky. A handful of airports (especially those catering to light-sport or experimental aircraft) sell unleaded avgas like Swift UL94—a high-octane, ethanol-free fuel that’s fully approved for all Rotax engines. It’s essentially aviation-grade MOGAS, and when available, it’s the perfect solution: clean, stable, and no hauling required.

But at most airports, the pump is blue and the choices are simple: 100LL, or nothing.

That’s why many Rotax owners adopt a hybrid strategy—using MOGAS when they can haul it safely to their home base, and 100LL when they’re on cross-country trips. The engine doesn’t care as long as you follow the right maintenance routine for whichever fuel you use most.

Cost

Here’s where MOGAS shines. A gallon of premium auto gas (even ethanol-free) can be $2–$3 cheaper than avgas. Over hundreds of hours, that difference adds up fast. And it’s not just the price per gallon—you’ll also save on maintenance: fewer oil changes, fewer spark plugs, and fewer lead-related cleanouts.

If you’re using 100LL regularly, you’ll likely add Decalin (a lead-scavenging additive) to your fuel and stick to 50-hour oil changes. Those costs chip away at 100LL’s convenience advantage.

Meanwhile, UL94—where available—usually sits somewhere in the middle on price, typically a few cents cheaper than 100LL but with all the benefits of unleaded fuel.

Fuel Quality and Handling

MOGAS requires a little more care in handling. It’s not stored or filtered like avgas, so it’s up to you to make sure it stays clean and fresh. Most experienced Rotax pilots use dedicated, aviation-grade containers, fill from busy stations (where turnover is high), and pour through a Mr. Funnel or filter system to catch water and debris.

Freshness also matters. Auto gas doesn’t like to sit. After a few months, especially in vented tanks, it can lose volatility or even gum up injectors. A stabilizer additive helps, but the best rule of thumb is simple: use what you buy within a few weeks.

Storage and Shelf Life

This is one area where avgas still wins. 100LL can sit for a year or more with no noticeable degradation. MOGAS? Not so much. After a couple of months, octane begins to drop, especially if it’s been exposed to temperature swings or humidity.

That’s why many Rotax owners fill up with 100LL before long winter breaks or extended downtime. It’s not just about convenience—it prevents varnish, corrosion, and moisture absorption.

Still, if your airplane flies regularly, MOGAS storage isn’t a problem. Keep it sealed, rotate your supply, and top off tanks to minimize condensation.

Bottom line:

100LL is the king of convenience, but MOGAS is the king of cleanliness—and your wallet knows it. The real trick is figuring out how to get MOGAS to your airplane without turning refueling into a CrossFit workout. For most of us, that means using 100LL on the road and unleaded fuel at home, whenever we can make it work.

Fighting the Lead Monster

If you fly a Rotax in the U.S., chances are you’ll end up burning 100LL at least some of the time. That’s fine—Rotax designed the iS series to handle it—but the real problem isn’t the fuel itself, it’s the lead inside it.

Leaded avgas is a relic from another era, and while it gives us great detonation protection, it also leaves behind a trail of gray misery: spark plug fouling, oily sludge, and lead crystals in the gearbox that look like something out of a geology lab.

Enter the unsung hero of the Rotax world: Decalin RunUp.

What It Does

Decalin is a lead scavenger—a chemical additive that helps prevent the lead from sticking where it shouldn’t. When added to 100LL, it reacts with tetraethyl lead during combustion and turns it into lead phosphate, a soft, powdery compound that either exits through the exhaust or stays suspended in the oil instead of plating onto valves and plugs.

In short, Decalin doesn’t remove lead—it just keeps it from turning into concrete inside your engine.

Rotax doesn’t officially “approve” any additives in its manuals, but acknowledges their successful use in the field, and both Rotax service centers and mechanics routinely recommend it when operating on avgas.

How to Use It

The dosing is simple: 1 ounce of Decalin per 10 gallons of 100LL (some owners bump it slightly to 1.5 oz for extra protection). Add it to the tank before or during fueling so it mixes evenly.

A bottle costs about $35 and treats hundreds of gallons—cheap insurance compared to the cost of a gearbox teardown. You’ll know it’s doing its job when you see a faint white residue on your exhaust pipes. That’s lead phosphate, the harmless byproduct of the reaction.

Things to Watch

If your Rotax has an oxygen sensor (as all iS engines do), Decalin can coat the sensor over time. It’s not a dealbreaker—just clean or inspect the O₂ sensor occasionally, especially if you’re running long stretches of 100LL. Alternating with unleaded fuel helps keep the sensor clear.

And while Decalin works wonders, it’s not a free pass to skip maintenance. You still need to:

- Stick to 50-hour oil changes (or 25 if you’re mostly on avgas).

- Use semi-synthetic oil that can handle lead (AeroShell Sport Plus 4 or equivalent).

- Periodically clean the oil tank and plugs.

Also, never use automotive “lead substitutes” or mystery fuel cleaners—those are designed for old car engines, not high-compression aircraft powerplants. Stick to Decalin RunUp or the equivalent TCP formula made for aviation.

Using MOGAS Safely

So you’ve decided to join the clean-burn club and feed your Rotax the good stuff—premium MOGAS. Smart move. But before you start hauling gas from your local Chevron, there are a few things to keep in mind. MOGAS is excellent fuel, but it wasn’t designed for airplanes, and that means you become part of the quality-control department.

Ethanol: Friend, Foe, or Just Misunderstood?

Rotax officially approves MOGAS with up to 10% ethanol (E10). The engines themselves handle it fine—fuel lines, injectors, and seals are all rated for it. The bigger concern is your airframe, not the engine. Older hoses, tanks, or gaskets may not love ethanol, so always check your aircraft manufacturer’s documentation before assuming it’s safe.

If you can find ethanol-free premium (E0), great—it’s the gold standard. But if E10 is all that’s available, it’s perfectly acceptable as long as your airframe materials are compatible.

Moisture and Phase Separation

Ethanol loves water—it’s hygroscopic—and that can become a problem in a vented tank exposed to humid air. Over time, the ethanol can absorb moisture, which eventually “phase separates,” leaving a layer of water-rich ethanol at the bottom of the tank. Not ideal for flight.

You can prevent this by:

- Keeping your fuel tanks as full as possible when parked.

- Using the fuel regularly—don’t let it sit for months.

- Sumping your tanks religiously before flight, especially after long or damp storage.

If you suspect phase separation (milky or uneven fuel samples), don’t risk it—drain and refill with fresh fuel.

Testing and Verification

Not sure if the gas station’s “Premium” really means ethanol-free? Perform the simple water separation test:

- Put some water in a clear tube or bottle.

- Add a small amount of the fuel.

- Shake and let it settle.

If the water level rises, you’ve got ethanol. No change means it’s clean E0 fuel.

Online databases like pure-gas.org also list ethanol-free stations by ZIP code—a great resource for pilots trying to find reliable sources.

Seasonal Blends and Vapor Lock

Automotive fuel changes with the seasons. Winter-blend MOGAS has higher vapor pressure so cars start easily in the cold—but that same volatility can cause vapor lock in summer heat or high altitudes. Always use season-appropriate fuel, and if you’re unsure what blend you have in the can, consider mixing in a bit of 100LL to reduce vapor pressure.

If you’re flying in hot weather, a few simple precautions help:

- Avoid long ground idles after refueling.

- Run both electric pumps during taxi and takeoff (the iS system already manages this).

- Don’t let “old” winter gas sit around until July—it’s a recipe for vapor lock.

This is the authoritative and detailed a presentation by Ron Singh about MOGAS blends, the risk for vapor lock, and an analysis of the impact of vapor in the fuel system:

Handling and Storage

Think of yourself as the FBO now. That means clean containers, proper filtration, and rotation. Use aviation-grade jerry cans with tight seals, store them out of sunlight, and filter every pour through a Mr. Funnel or equivalent. Buy from busy gas stations where the fuel turnover is high—freshness is everything.

If you fly frequently, this process becomes second nature. If you fly occasionally, consider using avgas during long storage periods and mogas for your regular flights.

Bottom line:

MOGAS rewards good habits. Treat it like the sensitive, high-performance fuel it is—keep it clean, dry, and fresh—and it’ll return the favor with smoother operation, lower costs, and a much cleaner engine.

The Future Is Unleaded

The good news for Rotax owners? The world is finally catching up to what our engines have wanted all along. The era of leaded avgas is winding down — not just a dream anymore, but a defined roadmap.

While most certified piston engines still rely on 100LL, your Rotax iS-series engines were designed around unleaded fuel. That means when the industry finally transitions away from leaded avgas, your engine’s ready—no major mods required.

The U.S. is working through the integrated government-industry initiative EAGLE (Eliminate Aviation Gasoline Lead Emissions), which has set the goal of eliminating leaded avgas for piston-engine aircraft by the end of 2030.

Additionally, the FAA Reauthorization Act of 2024 reinforces that 100LL must remain available at least until the end of 2030 (or until a certified unleaded alternative is available). In Alaska, the availability of 100LL is extended to the end of 2032.

Also, some U.S. states are aligning their own laws—for example, California passed legislation banning leaded avgas sales from 2031, to mirror the federal goal.

In short:

- 2030 is the target year for a full transition to unleaded aviation gasoline in the U.S.

- Until then, 100LL will still be available—so you’re not forced off it yet.

- Transition speed will depend on certification of fuels, distribution infrastructure, and aircraft/engine approvals.

Already out there is Swift Fuels UL94 (94-octane unleaded avgas) and GAMI G100UL (100-octane unleaded). These represent near-term stepping stones toward the full 100-octane drop-in solution. Many Rotax owners view UL94 as the “here-and-now” upgrade and are monitoring G100UL/100R closely.

For Rotax owners, this transition is less disruptive than for many. The iS-series engines are already designed to work with unleaded automotive fuels (MOGAS) and modern assured-octane fuels. When the industry flips the switch to full unleaded aviation fuel, you’ll simply keep flying—cleaner, cheaper, less hassle.

Bottom line:

The era of 100LL is fading. A transition to unleaded aviation fuel by the end of 2030 is firmly on the roadmap in the U.S. For you and your Rotax, that means your engine is already ahead of the curve—and when it becomes routine to fly on unleaded fuel, you’ll be ready.

Key Takeaways

If you’ve made it this far, congratulations — you now know more about Rotax fuel chemistry than most people at the airport pump. But to make it easy, here’s the distilled version:

- Rotax loves unleaded fuel: Your Rotax iS-series engine was designed from the start for unleaded gasoline. When you run premium MOGAS or unleaded avgas like Swift UL94, you get cleaner oil, longer service intervals, and happier spark plugs.

- 100LL is fine — if you manage it Leaded avgas is safe to use, but not ideal. Stick to 50-hour oil changes (or 25 if you’re mostly on 100LL), use semi-synthetic oil like AeroShell Sport Plus 4, and add Decalin RunUp to keep the lead soft and manageable.

- Performance is the same: There’s no horsepower difference between fuels. What changes is how much cleanup the fuel leaves behind. Use unleaded for day-to-day flying, and avgas for long storage, hot weather, or cross-country trips where mogas isn’t available.

- Vapor lock and ethanol are manageable: The Rotax iS fuel system is pressure-fed and resistant to vapor lock, but pure MOGAS can still be volatile in hot weather. Mixing a small amount of 100LL (10–25 %) can lower vapor pressure and eliminate vapor-lock concerns. Ethanol up to 10 % (E10) is approved — just confirm your airframe components are compatible and keep the fuel dry and fresh.

- Cost and convenience balance out: MOGAS is $2–$3 per gallon cheaper, and maintenance savings compound that advantage. 100LL wins on convenience, but not on long-term cost or cleanliness.

- The future is firmly unleaded: The FAA’s EAGLE program targets the end of leaded avgas by 2030 (2032 in Alaska). Swift UL94 is already approved for all Rotax engines, and 100-octane unleaded fuels like GAMI G100UL and Swift 100R are coming soon. The transition won’t disrupt Rotax owners — your engine is already future-proof.

My Plan Going Forward

After digging through the data, the manuals, and more forum rabbit holes than I care to admit, the conclusion for me is clear: there’s no single “perfect” fuel — just smart fuel management.

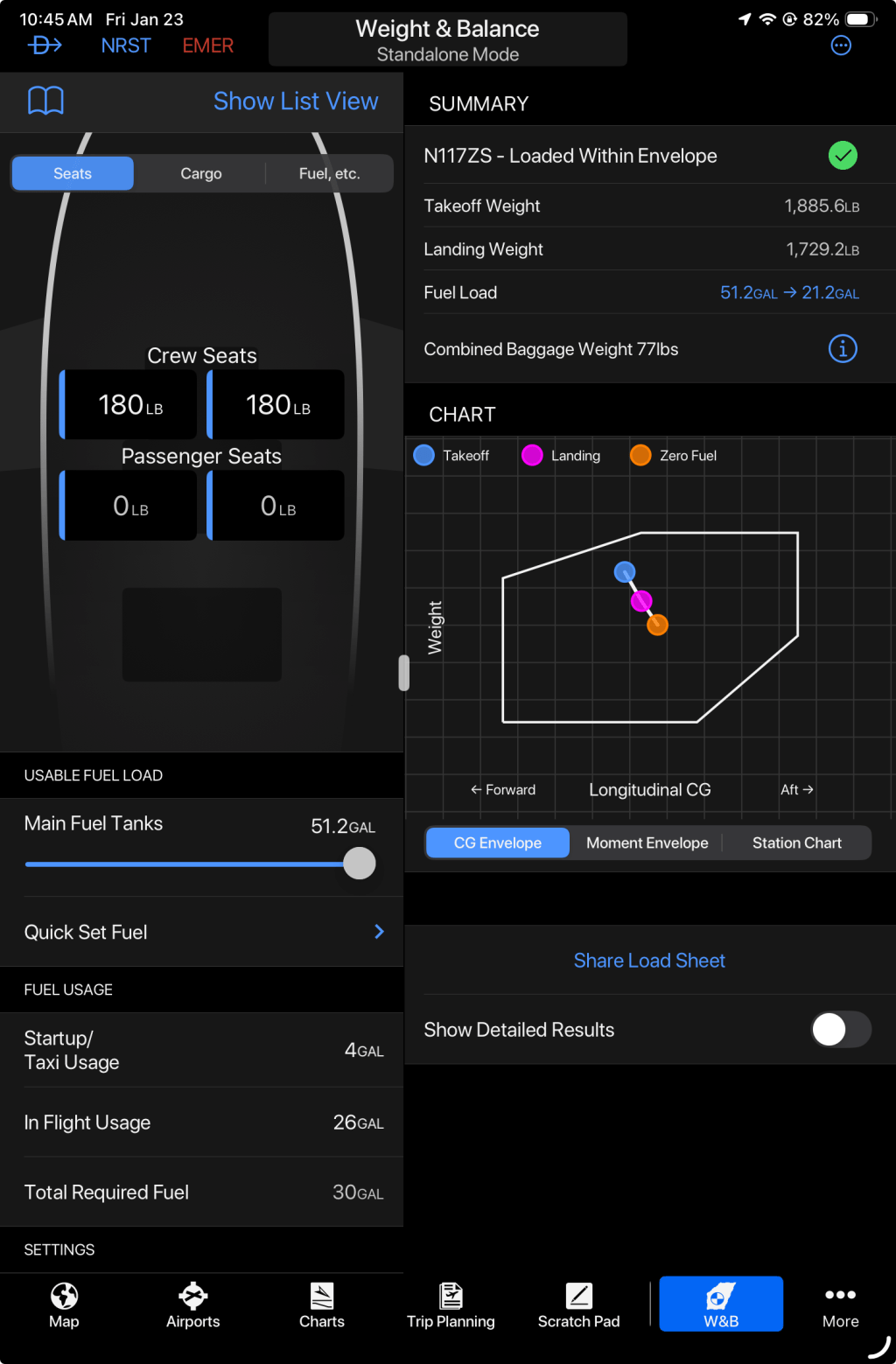

Here’s my plan for N117ZS and its Rotax 916iS:

- Start with 100LL + Decalin. While I’m getting the airplane flying and sorting out logistics at KAWO, I’ll use 100LL from the airport pump. It’s consistent, easy, and safe — especially for a new engine in early flight testing. Adding Decalin will help keep the lead soft and manageable.

- Build a system for MOGAS at home base. I plan to set up a small, sealed fuel storage and transfer setup in my hangar so I can haul in premium ethanol-free MOGAS. It’s a bit of work up front, but worth it for cleaner oil and longer maintenance intervals.

- Use MOGAS for local operations. Once the home fueling system is dialed in, MOGAS will be my default for everyday flying — cleaner, cheaper, and what the engine really prefers.

- Use 100LL on cross-country trips. When I’m away from home and the only option is the blue pump, I’ll top off with 100LL without hesitation. I’ll just treat the oil change clock as if it started ticking faster.

- Stick to 50-hour oil changes regardless of fuel. It’s simple, conservative, and keeps the engine happy whether I’m running unleaded, avgas, or a mix.

In other words, I’m taking a hybrid approach — MOGAS when I can, 100LL when I must. It’s the same strategy that many experienced Rotax owners have adopted, and it aligns perfectly with how the airplane will actually be used.

The way I see it, this isn’t about purity — it’s about practicality. 100LL keeps me moving on trips, MOGAS keeps my engine clean at home, and the maintenance schedule keeps me honest. And when the day finally comes that every airport sells unleaded avgas, I’ll be more than ready to say goodbye to the blue stuff for good.

Leave a comment