TL;DR: This post compares the Rotax 915iS vs 916iS, the first and most defining decision of my Sling TSi build. The newer 916iS—nicknamed “The Impossible Engine”—delivers 19 more horsepower, a 2000-hour TBO (vs 1200 on the 915iS), and better fuel efficiency while adding only about eight pounds. Inside, it’s almost a new engine, with redesigned internals, upgraded systems, and its own synthetic oil. Despite the higher upfront cost, its longer life and efficiency make it cheaper to operate, and the extra power provides noticeably stronger climb and takeoff performance at high-density-altitude airports. For me, the 916iS was the clear choice to power a modern, capable Sling TSi.

Before there was Slingology blog, before the spreadsheets and the late-night option debates, there was this decision — 915iS or 916iS. When I ordered the kit in November 2024, this was the very first fork in the road.

The Rotax 915iS was the proven workhorse: reliable, widespread, well-documented, and backed by tens of thousands of flight hours in the field. Its 141 horsepower had become the de facto standard for high-performance Light Sport and Experimental aircraft, including the Sling TSi.

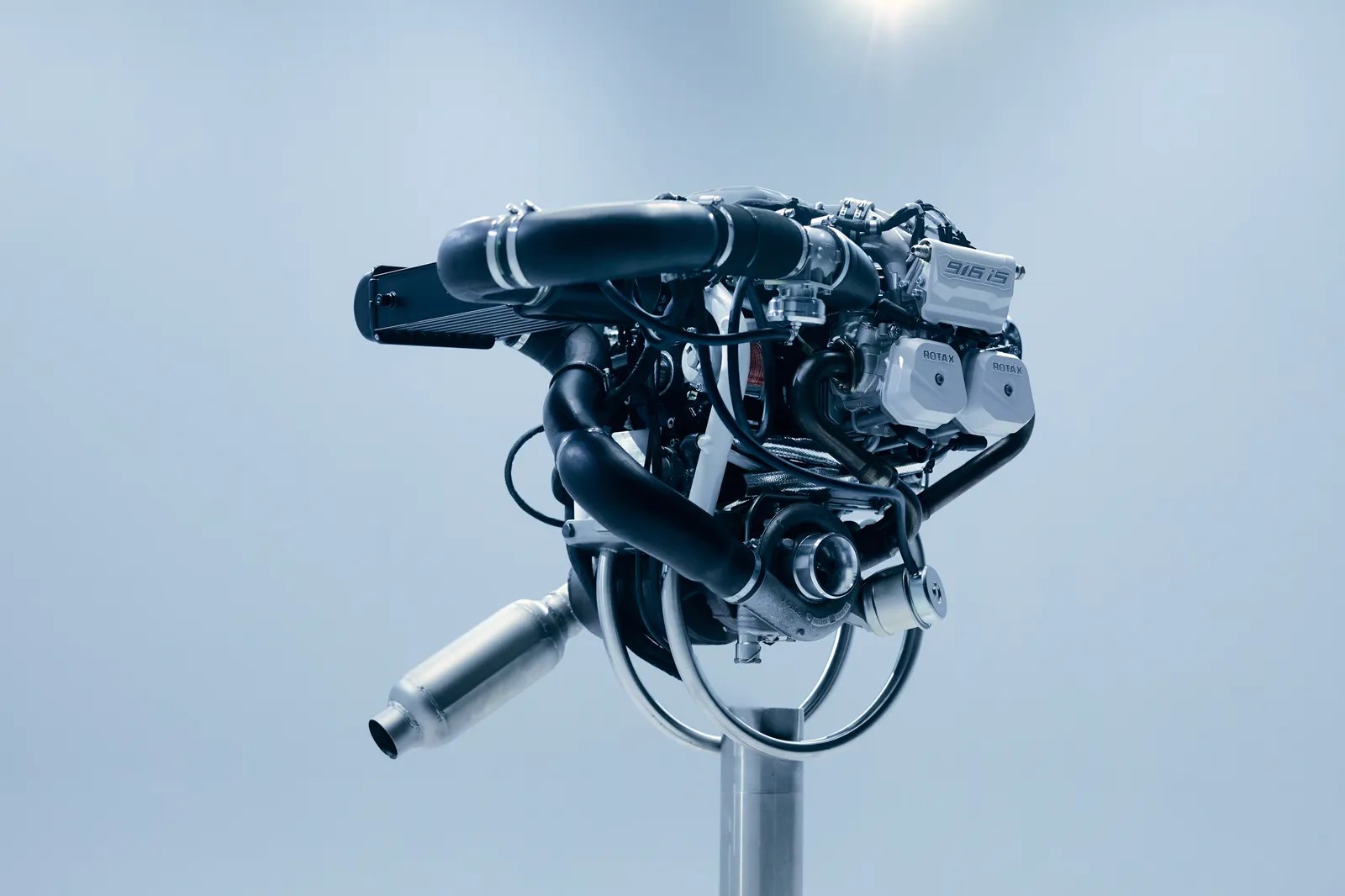

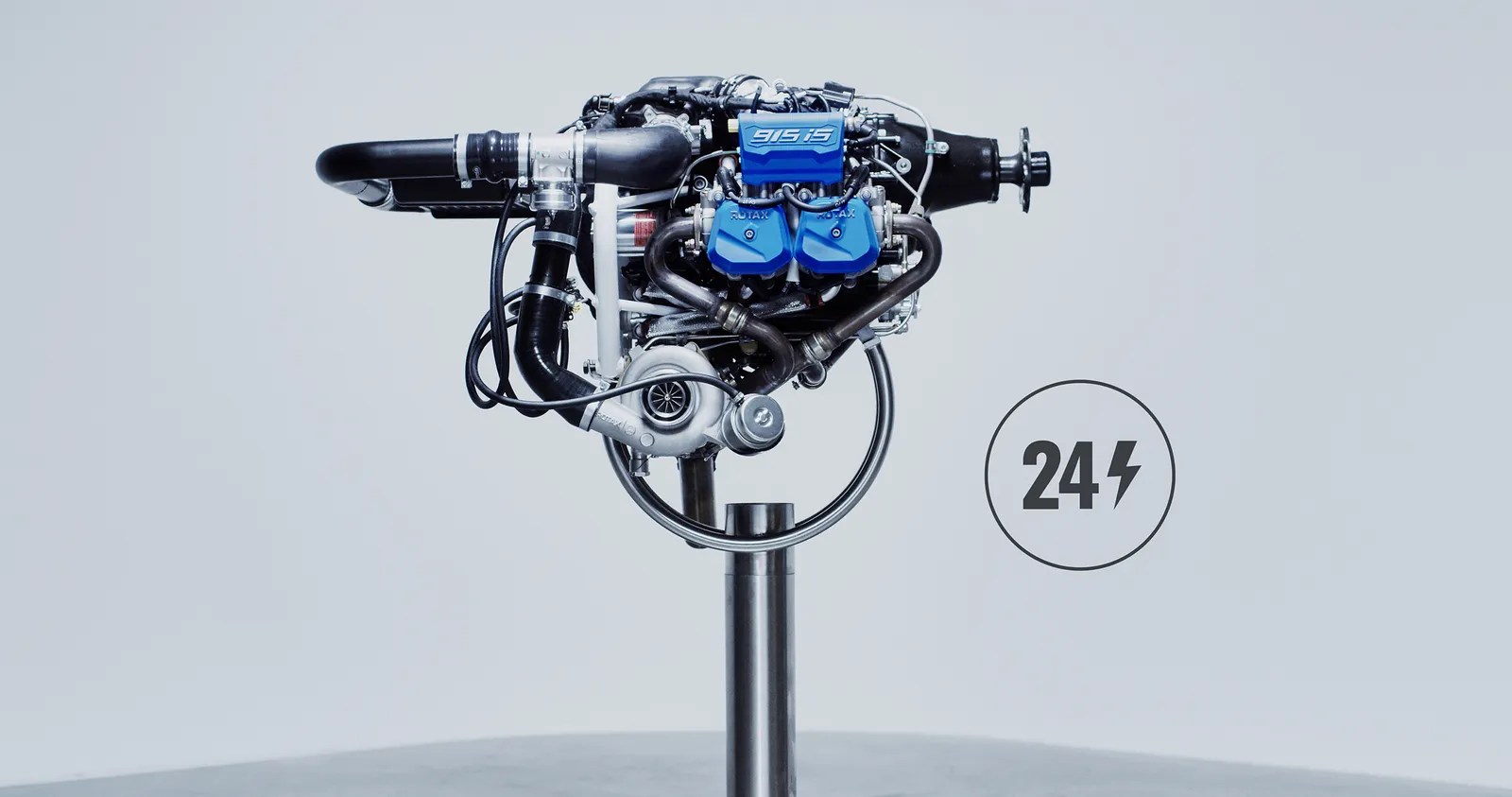

Then Rotax unveiled the 916iS — a newer, more powerful sibling with 160 horsepower (for five minutes), a longer 2000-hour TBO, and a list of internal improvements so extensive that calling it a “915iS upgrade” feels like underselling it. It was marketed as “The Impossible Engine,” a project Rotax engineers supposedly began with the goal of producing more power and better fuel efficiency without increasing weight — something many said couldn’t be done.

Yet they did it.

That framing alone made this decision more than a spec-sheet exercise. It was a philosophical one: do you go with the known quantity, or the newer, slightly pricier evolution — the engine that pushes the boundaries of what a modern GA powerplant can be?

When I started this project, my guiding principle was simple: build the most modern Sling TSi feasible — not the cheapest or the fastest build, but the one that would feel state-of-the-art five or ten years from now. That compass pointed squarely toward the 916iS.

Rotax 915iS vs 916iS — Overview and Comparison

On paper, the 916iS looks like a simple evolution of the 915iS — same displacement, same basic architecture, same 5800 RPM limit. In practice, it’s more like a complete re-engineering of the 9-series DNA. Both are turbocharged, fuel-injected, liquid-cooled four-cylinders that share the familiar Rotax layout and reputation for efficiency. But the similarities end there.

| Specification | Rotax 915iS | Rotax 916iS |

|---|---|---|

| Max Takeoff Power | 141 HP @ 5800 RPM | 160 HP @ 5800 RPM (5 min) |

| Max Continuous Power | 135 HP @ 5500 RPM | 137 HP @ 5500 RPM |

| TBO (Time Between Overhaul) | 1,200 hours | 2,000 hours |

| Dry Weight | ~210 lbs | ~218 lbs |

| Fuel Type | MOGAS / 100LL | MOGAS / 100LL |

| Altitude Power Retention | Up to 15,000 ft | Up to 15,000 ft |

| Electrical System | 12V (24V charge capability) | 12V (24V charge capability) |

| List Price (Nov 2024) | $43,738 | $51,398 |

| List Price (Nov 2025) | $48,465 | $61,980 |

The difference that matters most isn’t just the numbers — it’s what they represent.

Rotax took a platform already known for its power-to-weight ratio and found a way to squeeze out 19 more horsepower at takeoff, increase the TBO by 800 hours, and reduce fuel burn by roughly 10–15% at equivalent output — all while adding less than ten pounds.

To achieve that, they had to rethink nearly every major internal component.

We’ll dive into those details in the next section — but suffice it to say, the 916iS isn’t a “tuned” 915iS. It’s a fundamentally different machine wearing the same badge.

And while both engines remain certified under EASA CS-E and ASTM standards, Rotax made one thing clear: the 915iS will not receive a TBO extension to 2000 hours. The internal improvements that make the 916iS capable of that lifespan simply cannot be retrofitted.

It’s no wonder the 916iS earned the nickname “The Impossible Engine.”

Rotax’s engineers didn’t just chase more horsepower — they rebuilt the foundation to make that power sustainable.

The Impossible Engine — How Rotax Did It

When Rotax engineers began sketching out the next step beyond the 915iS, they set themselves an audacious goal: increase power and efficiency without adding weight.

It sounded like an engineering contradiction — hence the project’s nickname inside Rotax: “The Impossible Engine.”

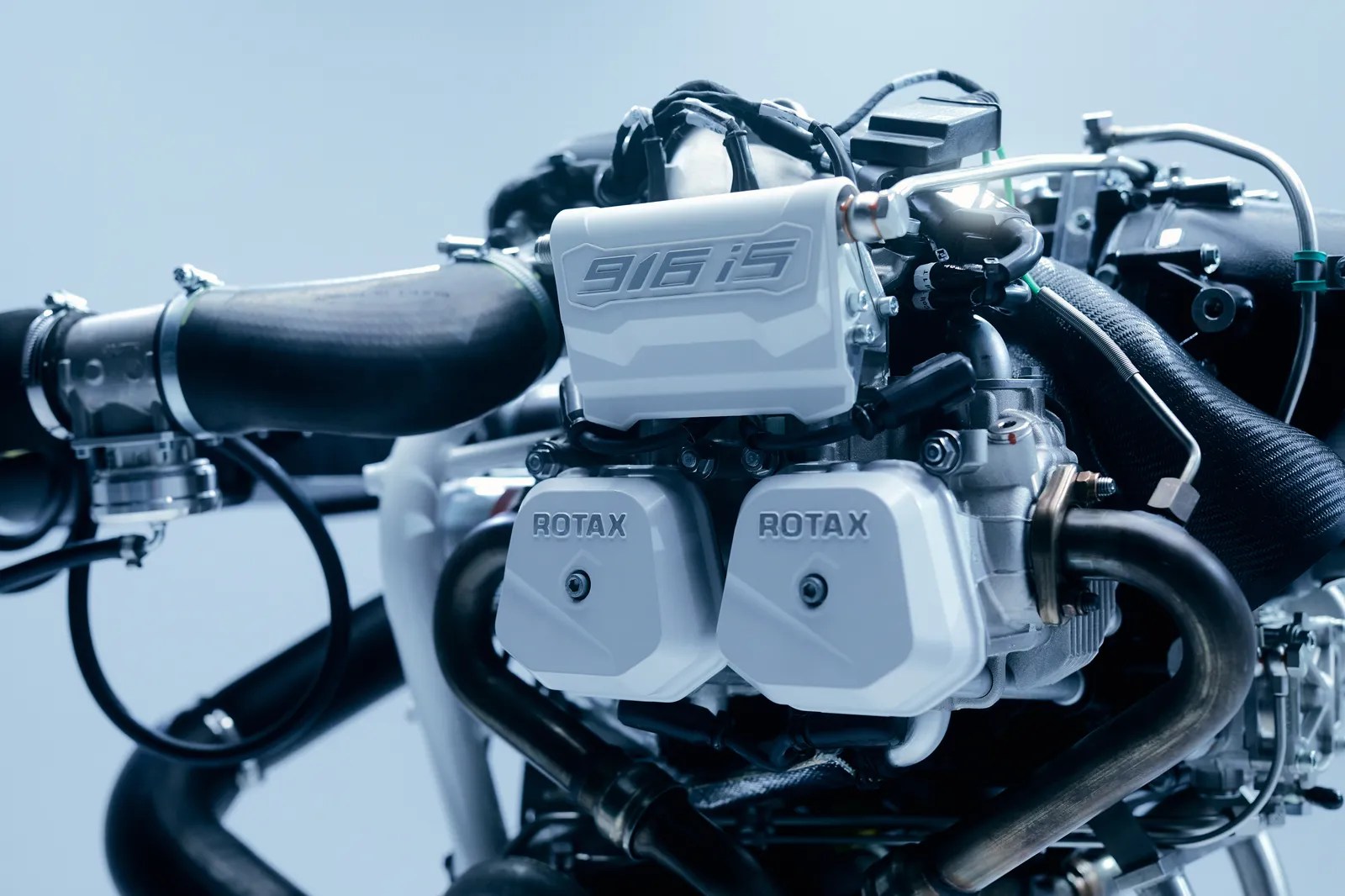

The 915iS was already a benchmark in the light-aircraft world — a 141-horsepower, turbocharged marvel capable of holding full power up to 15,000 feet. But after years of real-world data, Rotax engineers knew exactly where the margins were. To get more power reliably, they had to start from the inside out. The 916iS may look like a 915iS from the outside, but under the cowling, more than 20 major components were redesigned or replaced.

Here’s a quick tour of what changed — and why it matters:

Smarter Breathing and Burning

- New camshaft profile allows greater airflow into the cylinders, improving combustion efficiency.

- Recontoured rocker arms reduce wear and improve valve timing precision.

- Higher boost pressure from the turbocharger increases air volume, which demanded stronger intake connections and a larger intercooler — nearly four inches wider than the 915’s.

Stronger Heart, Cooler Head

- Reinforced crankcase with new machining around main webs to handle higher cylinder pressures.

- New crankshaft and bearings with added material strength and coatings designed for 2000-hour durability.

- Redesigned pistons with new ring packs, modified compression ratios, and a specialized skirt coating to withstand the increased loads and heat.

- Improved cooling with optional air guides and larger intercooler — crucial for high-power climb testing on hot days.

Fuel, Fire, and Force

- Upgraded dual fuel pumps purpose-built for the 916iS to maintain proper pressure at higher boost levels.

- New ignition coils with stronger spark output, critical for reliable combustion under higher pressure.

- Revised ECU mapping calibrated on MOGAS for optimal mixture control (using lambda sensors during testing).

- New muffler and “after-muffler” design to reduce back pressure and meet strict European noise limits without sacrificing thrust.

Power Transmission Reinvented

- New gearbox internals with higher torque capacity.

- Thicker prop flange and new bolt pattern allow the use of heavier, more robust constant-speed props.

- Upgraded clutch for smoother torque transfer and reduced vibration.

The Secret Ingredient: New Oil

The internal loads were so different that Rotax had to develop a new fully synthetic oil (5W50) specifically for this engine. Aeroshell Sport Plus 4, the long-time standard for Rotax engines, could no longer provide the needed protection under the 916’s pressure and temperature conditions. The new formulation — still compatible with MOGAS and 100LL — was the final piece of the puzzle that made the 2000-hour TBO possible.

In the End: More Power, Less Fuel

When the test bench data came in, it confirmed the impossible:

- +19 HP at takeoff (160 vs. 141)

- +2 HP continuous (137 vs. 135)

- ~10% less fuel burn at full power

- ~20% less fuel burn at max continuous

And all of that while adding less than ten pounds and stretching the TBO by 800 hours. Rotax didn’t just refine the 915iS — they effectively built a new engine that happens to fit in the same mounts.

If you are an EAA member (and if not why not), you can watch a very detailed and a comprehensive webinar that describes the 916iS architecture and internals:

It’s a quiet kind of innovation — not a revolution announced in bold fonts, but one that shows up in climb rates, cylinder temps, and overhaul intervals.

The Cost Equation

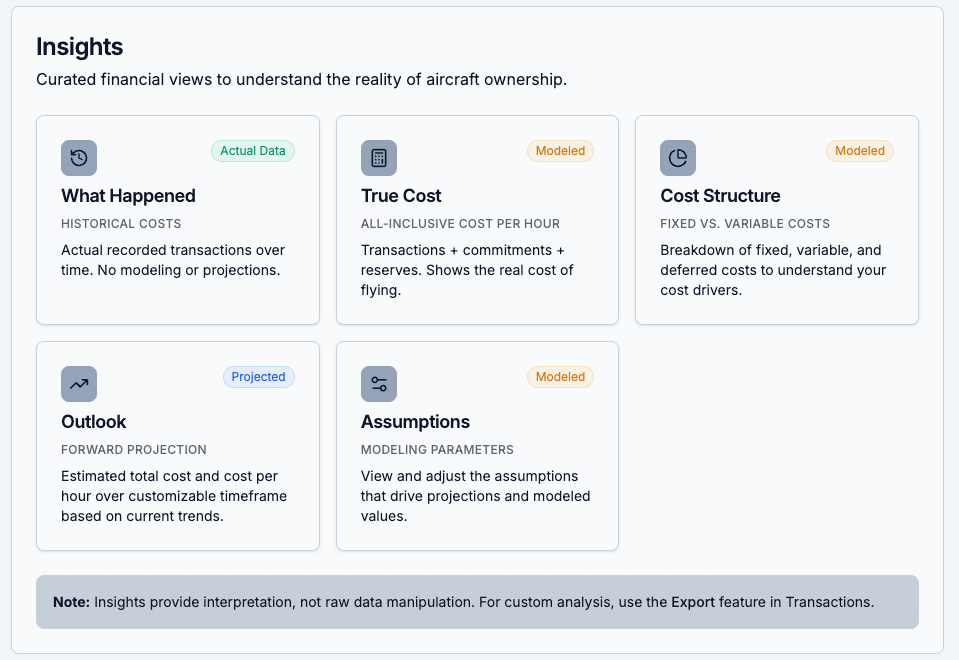

Power and reliability are great, but at some point every engine decision ends up in a spreadsheet. To compare the 915iS and 916iS in a way that matters to an owner, I looked at cost per flight hour to TBO under two different maintenance philosophies:

- Scenario A – Overhaul at 65% of engine cost

- Scenario B – Full replacement at 100% of engine cost

This isn’t a prediction of what any specific shop will charge; it’s a modeling tool. The 65% number is a common rule of thumb for overhaul cost relative to new-engine price.

The formula for each scenario:

- Scenario A (Overhaul) Cost/hr = (0.65 × Engine Price) ÷ TBO

- Scenario B (Replace) Cost/hr = (1.00 × Engine Price) ÷ TBO

2024 Pricing (When I Ordered)

| Engine | Price | TBO (hr) | Scenario A Overhaul @ 65% | Scenario B Full Replacement |

|---|---|---|---|---|

| Rotax 915iS | $43,738 | 1,200 | $23.69/hr | $36.45/hr |

| Rotax 916iS | $51,398 | 2,000 | $16.70/hr | $25.70/hr |

Even in the more conservative full replacement scenario, the 916iS comes out ahead. For the price premium you pay up front, the longer TBO and higher durability pull the cost per hour down significantly compared to the 915iS.

2025 Pricing (Today – Nov 25)

Rotax prices have climbed since I placed my order:

- 915iS: $43,738 → $48,465

- 916iS: $51,398 → $61,980

Here’s how that changes the math.

| Engine | Price | TBO (hr) | Scenario A Overhaul @ 65% | Scenario B Full Replacement |

|---|---|---|---|---|

| Rotax 915iS | $48,465 | 1,200 | $26.25/hr | $40.39/hr |

| Rotax 916iS | $61,980 | 2,000 | $20.14/hr | $30.99/hr |

Both engines get more expensive per hour with the new pricing, but the relationship stays the same:

- The 916iS still has a lower cost per hour in both scenarios.

- The gap is especially noticeable if you assume replacement rather than overhaul — the penalty of a shorter TBO really bites the 915iS.

As for why prices have jumped this much, we’re left to speculate: currency fluctuations, post-pandemic supply chain costs, EU manufacturing and labor costs, maybe even tariff and regulatory overhead. Whatever the cocktail, it’s not unique to Rotax — but it makes the TBO and efficiency advantages of the 916iS even more important.

For someone planning to actually use the airplane — long cross-country trips, IFR training, real yearly hours — these numbers make the 916iS look less like a luxury upgrade and more like a rational long-term choice.

Power and Efficiency — What It Means in Practice

Numbers on a spec sheet are one thing. What they mean in the air is another.

For a Sling TSi, the jump from 141 to 160 horsepower doesn’t just make takeoffs feel livelier — it changes the operational envelope in subtle but important ways.

Takeoff and Climb

The extra 19 horsepower is most obvious where it matters most: takeoff and initial climb.

The Sling TSi with a 915iS is already a solid performer, showing around 1,200 fpm climb and ~820 ft takeoff over a 50-ft obstacle at sea level on a standard day.

The 916iS doesn’t alter the airframe, but its additional five-minute takeoff rating (160 hp vs 141 hp) typically delivers a 10–15 percent improvement in climb performance during that window.

To make this less abstract, here’s an illustrative comparison. These are not POH numbers — just reasonable estimates that demonstrate how the power difference shows up in the real world.

Example: Sling TSi at Leadville, Colorado (KLXV)

- Field elevation: 9,934 ft

- ISA temperature at that altitude: ≈ 23 °F (–5 °C)

- Hot-day example: 90 °F (32 °C)

- Resulting density altitude: ≈ 14,500 ft

| Scenario | Density Alt. (approx.) | Engine | Takeoff over 50 ft (illustrative) | Initial Climb (illustrative) |

|---|---|---|---|---|

| Standard-day (ISA) | 10,000 ft | 915iS | ~1,800 ft | ~600 fpm |

| 916iS | ~1,600 ft | ~680 fpm | ||

| Hot day (90 °F) | 14,500 ft | 915iS | ~2,350 ft | ~380 fpm |

| 916iS | ~2,150 ft | ~430 fpm |

At Leadville, those extra 50 fpm of climb and a couple hundred feet less runway can easily be the difference between marginal and comfortable. As density altitude climbs into five digits, every additional horsepower buys tangible safety margin.

High-Altitude Performance

Both engines maintain maximum rated power up to 15,000 feet, but the 916iS does it more effortlessly. That means faster cruise climbs and less waiting for the VSI to catch up when transitioning from mountain passes or executing a high-altitude departure. Pilots who regularly fly cross-country in the western U.S. or mountainous terrain will feel the difference immediately.

Cruise and Efficiency

Rotax’s engineers didn’t just push the turbo harder; they redesigned how the engine breathes and burns fuel. The result:

- About 10% less fuel burn at full power, and

- Roughly 20% less fuel burn at max continuous (5500 RPM) compared to the 915iS.

That translates into real savings on long trips and a greater usable range per gallon — a subtle but meaningful benefit when flying over long stretches without easy refueling options.

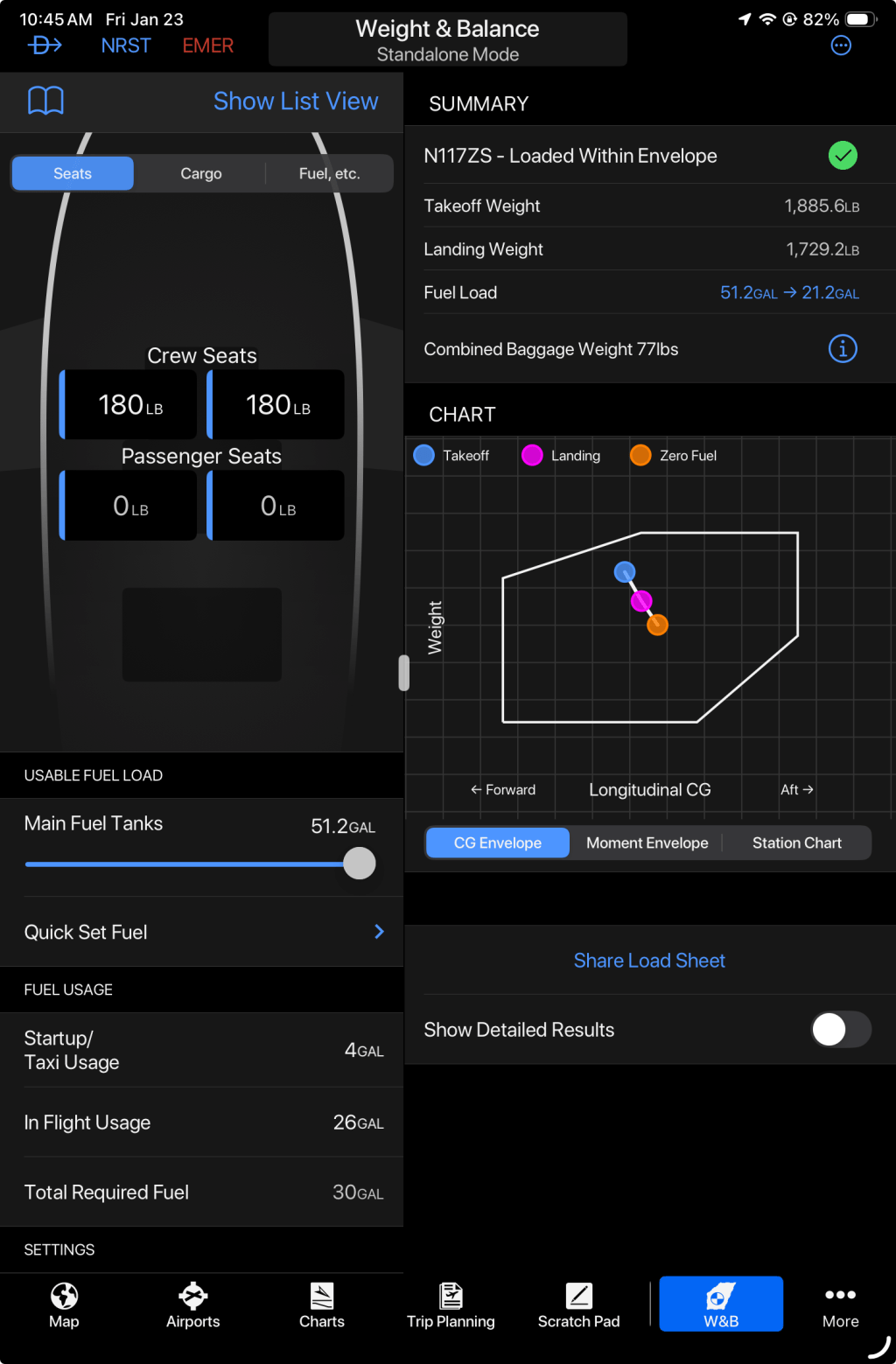

Weight and Balance

The 916iS adds about 8–10 pounds compared to the 915iS, a negligible change in a TSi’s overall CG range. In practice, you won’t feel the difference on the scales, but you will in climb rate and throttle response.

Sound and Smoothness

The redesigned muffler and after-muffler do more than satisfy European noise regulations — they also make the 916iS slightly quieter and smoother. It’s still a Rotax, which means a distinctive buzz at idle, but once at cruise power, the vibration and It also gives headroom for future loads — meaning the extra power provides a safety and performance margin when the airplane is carrying more weight or operating in less-than-ideal conditions. For example, adding optional equipment like an onboard oxygen system, carrying full fuel tanks for long cross-country legs, or bringing extra baggage for a trip all increase the aircraft’s gross weight.

While the Sling TSi’s structure and aerodynamics can handle those loads, climb performance and takeoff distance inevitably degrade as weight and density altitude rise. The 916iS’s additional horsepower helps offset those penalties, preserving strong climb rates and shorter takeoff rolls even when the airplane is heavy or operating on a hot day.

Why I Chose the 916iS

When I started this project, I set a simple charter for myself:

Build the most modern Sling TSi feasible.

That guiding principle has quietly shaped every configuration choice since — avionics, safety systems, materials, even paint. But it started here, with the engine.

The 915iS was the known quantity. It had the track record, the documentation, the data, and a healthy supply chain. It was — and still is — an exceptional engine. But the 916iS represented something more: a generational step forward.

It wasn’t just a few extra horsepower; it was a cleaner, more efficient, longer-lasting design — one that incorporated every lesson Rotax had learned from the 915iS fleet. The 2000-hour TBO, the reengineered internals, and the fuel efficiency gains were not marketing bullet points. They were the result of deep mechanical refinement — a quiet evolution aimed squarely at reliability and longevity.

Yes, it was more expensive — and yes, that number has only gone up since I placed the order. But when I ran the long-term cost-per-hour math, the equation turned out to be surprisingly rational. The 916iS wasn’t just the modern choice; it was the economically sound one over the life of the airplane.

And perhaps most importantly, it added a layer of capability and confidence that you can’t quantify on a spreadsheet — knowing that on a hot day, at a high field, or climbing through the haze on an IFR departure, there’s a little more power waiting under your right hand.

For a project that’s as much about learning as it is about flying, the 916iS fit the story perfectly: an engine born from an “impossible” challenge, powering an aircraft built to make ambitious ideas possible.

Leave a comment