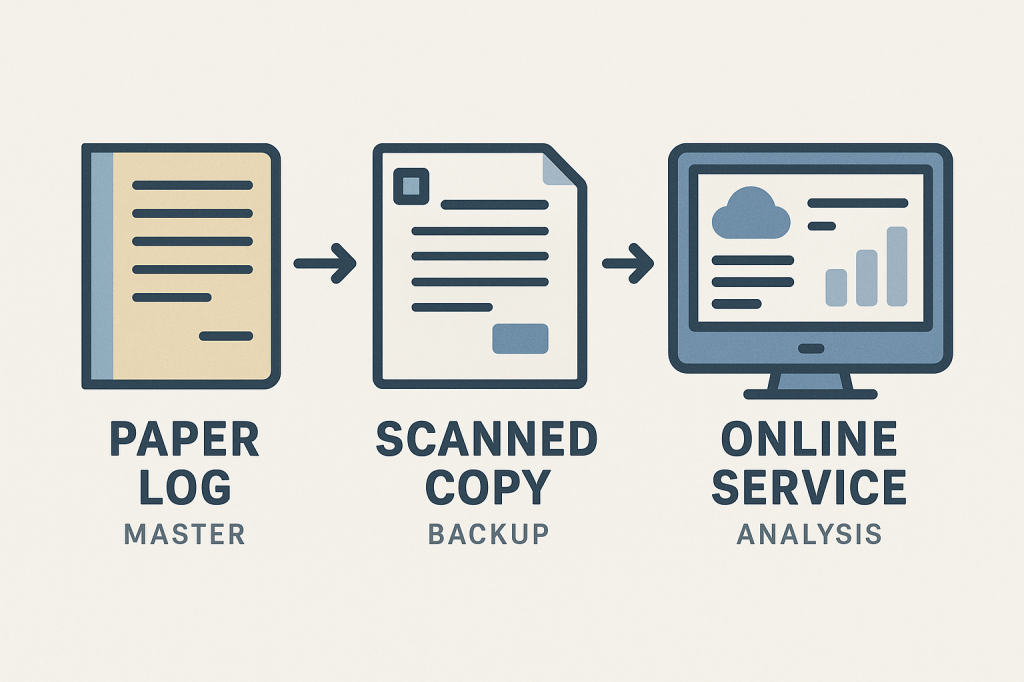

TL;DR: Aviation records must survive for decades, but digital tools rarely do. The most resilient approach for a GA pilot with a single airplane is a hybrid model: keep paper as the master, scan everything important as a backup, and use a lightweight online dashboard for reminders, planning, and analysis. This gives you permanence without losing the benefits of modern tools—and keeps your aircraft’s history under your control, not locked inside a service that may not be around tomorrow.

Aviation records live for decades. Your tools will not.

Every pilot I know loves their tools—EFBs, cloud logbooks, online maintenance trackers, apps that remind you to change your oil, apps that remind the other apps to remind you to change your oil. It’s a great time to be a technophile in general aviation.

But there’s one uncomfortable truth behind all this convenience:

Aviation records need to survive for decades.

Technology absolutely does not.

Pilot logbooks, maintenance histories, endorsements, component changes, SB compliance—these things outlive apps, platforms, subscriptions, even companies. And when you’re the owner of a single GA airplane, especially in the experimental world, you’re the only “IT department” your records will ever have.

This raises a simple question:

How do you keep long-lived aviation records in a world built on short-lived technology?

What follows is a practical philosophy for GA pilots and owners—a way to use modern digital tools without becoming dependent on them, and a way to keep your records organized, resilient, and future-proof no matter what happens in the cloud.

Next, let’s talk about why the most modern solution still begins with something surprisingly old-fashioned.

A Technophile Defending Paper

If you’re reading this, you’re probably like me: you love technology, you live inside an EFB, and you’ve already automated half your preflight. I track my flights with Garmin Pilot, file IFR with a swipe, and get real-time currency summaries from flyGarmin without touching a calculator. I’m the last person who should be advocating for… paper.

But here we are.

Because after looking at how long aviation records must survive—and how short the lifespan of apps, platforms, and cloud services really is—I’ve come to a very un-tech-bro conclusion:

For a GA pilot with a single airplane, the most modern record-keeping strategy still begins with old-fashioned ink.

Aviation lives on a different clock than technology:

- Pilot logbooks matter for decades.

- Aircraft maintenance records matter for the entire lifetime of the airframe—and often beyond that, through multiple owners.

- Experimental aircraft add even more nuance: SBs, SLs, and component histories don’t cleanly fit into the certified-world databases many digital tools rely on.

Meanwhile, most tech companies operate on a completely different timeline:

- Products change pricing, pivot, get acquired, or disappear.

- Even respected aviation logbook platforms have shut down, leaving pilots scrambling to retrieve years of entries.

- And the cloud—despite its convenience—has never been synonymous with permanence.

This creates a mismatch: aviation needs longevity, while technology promises features.

The trick is designing a system that benefits from both without becoming hostage to either.

That’s where the three-layer model comes in:

- Paper as the master,

- Scans as the insurance policy, and

- A digital dashboard as the intelligence layer that ties it all together.

This approach keeps you organized without locking your entire history into a single platform. It’s modern where it matters—analysis, reminders, integration—and old-school where permanence counts.

In the following sections, we’ll break down each of these layers and explain why, for a single GA aircraft owner, this hybrid method is not only simpler and cheaper—it’s safer and future-proof.

Why Paper Remains the Master

It feels almost heretical in 2025 to claim that paper is still the master record. But in aviation—especially for a single GA aircraft owner—it’s not nostalgia or tradition that keeps paper on top. It’s practicality, longevity, and a track record technology can’t match.

Digital tools are fantastic for day-to-day flying, analysis, and planning. But the historical, legal, and resale value of your flying life still rests on something that doesn’t crash, expire, or get bought by a private equity firm.

Here’s why.

1. Aviation Records Have a 30–50+ Year Lifespan

Aviation lives on a long timeline. Your apps do not.

- Your pilot logbook will matter for as long as you fly—and that’s often multiple decades.

- Your aircraft maintenance logs matter for the entire life of the airframe: annuals, condition inspections, engine time, prop histories, modifications, AD/SB compliance, and everything else that affects airworthiness.

Those records will likely outlive:

- Your current EFB

- Your phone

- Several operating systems

- Most of the cloud services you use today

Paper, by comparison, doesn’t go out of business and doesn’t need an API to be readable in 2050.

2. Long-Term Digital Solutions Gets Expensive Fast

This point is easy to overlook because subscriptions feel small month to month. But stretch them out over the lifespan of an airplane and the numbers are eye-opening.

- Pilot logbook apps typically run $60–$130 per year.

- Full digital aircraft records platforms (Bluetail, PlaneLogix, Coflyt) run hundreds to over a thousand dollars per year, plus four-figure onboarding or scanning fees.

Over 20–30 years, that’s easily tens of thousand dollars—even if nothing changes.

And things do change.

3. Digital Services Can—and Do—Disappear

Aviation has already seen real examples:

- mccPILOTLOG, once a major digital logbook, was abruptly discontinued. Users had corrupted exports, locked data, and in some cases no way to reinstall the software on new devices.

- Other pilot logbook apps have stagnated or stopped updating, leaving users trapped in outdated formats.

- Aviation maintenance platforms have changed pricing, removed free tiers, or reorganized features—forcing users into expensive plans just to keep their own history accessible.

- None of these services are regulated as other aviation industries do. In case of a disastrous failure that will cost your records, there is always the option for litigation, but who wants to deal with such complexities.

This isn’t fear mongering. It’s acknowledging the reality of software in the long arc of aviation life.

If you put your entire history in someone else’s service, you inherit every one of their risks.

4. Migrating to New Systems Is Painful

Even when a service doesn’t die, it can become obsolete enough that you have to leave it.

For pilots who lived through the mccPILOTLOG → CrewLounge forced migration, the pattern was familiar:

- Old apps stop supporting new OS versions.

- Desktop installers disappear.

- File formats become incompatible.

- Exports are partial or messy.

- Years of entries must be cleaned by hand.

For aircraft logs, migration can be even worse. If your maintenance records are trapped in a proprietary online interface, extracting everything—accurately, page by page, with dates and signatures intact—is tedious at best and impossible at worst.

Paper doesn’t have this problem. It’s always readable and always migratable.

5. Inspectors, Mechanics, and Buyers Still Trust Ink

This is the simplest reason—and one of the strongest.

When it comes to:

- proving flight time,

- showing endorsements,

- documenting work performed,

- validating airworthiness,

- or selling an airplane,

paper logbooks remain the gold standard.

DARs, IA mechanics, insurance auditors, and buyers all evaluate an aircraft’s value and history through its physical logs. A missing page, a damaged binder, or an incomplete ink trail directly affects resale value and trust.

Digital records are a useful supplement.

Paper is the proof.

6. Experimental Aircraft Make Digital Tracking Even Less Reliable

Certified-aircraft-centric tools rely heavily on:

- standard type certificates,

- factory configurations,

- FAA AD databases,

- and predictable maintenance schedules.

Experimental aircraft break all of those assumptions:

- AD applicability is nuanced (often “not applicable,” but SBs or SLs matter).

- Engines, props, avionics, and components may not be TSO’d.

- Custom modifications can break automatic tracking.

- Shops vary widely in how they document work.

A one-size-fits-all digital tracking platform often gives incomplete or misleading results. Paper logs, by contrast, capture exactly what happened, regardless of certification category.

Why Scanned Copies Are Essential

If paper is the master record, then scanned copies are the insurance policy. Not a luxury, not a “nice to have”—a critical second layer that protects you from the unpredictable realities of owning a single GA airplane for decades.

This isn’t about replacing paper. It’s about preserving it.

1. Scans Protect Against Catastrophic Loss

You can do everything right and still lose your logs:

- A hangar leak

- A house fire

- A stolen flight bag

- Mold in storage

- A misplaced binder during an annual

- A well-meaning helper who reorganizes your shelves “efficiently”

Paper lasts longer than software, but it’s still vulnerable to the physical world.

A clean PDF portfolio stored in cloud storage, and maybe a second offline copy—takes that vulnerability off the table. Catastrophic loss becomes a recoverable event, not an irreversible tragedy.

And for aircraft maintenance logs, where missing pages directly affect resale value, insurance disputes, and airworthiness, this protection is non-negotiable.

2. Scanned Logs Create a Permanent, Searchable Archive

Even if you never go fully digital, a complete scanned record set has real, everyday utility:

- You can quickly search past entries for part numbers, SB compliance, or component swaps.

- You can compare signatures, dates, and maintenance sequences without flipping through binders.

- You can share pages electronically with mechanics, sellers, insurers, and DARs without mailing or hand-delivering originals.

- You can organize logs chronologically even if your physical books are split across multiple volumes.

In other words: scans turn paper into a practical, modern resource—while leaving the originals untouched.

3. Scanning Keeps You Future-Ready: Log Transcription Is Now a Commodity

You don’t need to commit to a fully digital logbook today. That’s part of the beauty of the hybrid model.

By scanning now, you preserve the option to go digital later—because your scans become the raw material for transcription services. A growing number of companies specialize in:

- Converting handwritten pilot logbooks into structured electronic records

- Importing those records into apps like LogTen, Logbook Pro, or CrewLounge

- Auditing entries for completeness or compliance

- Reconstructing totals and applying standard formats

Examples include Anytime Logbooks, DigitalPilotLog, AcuLog, and other dedicated conversion services. Some charge line-by-line, others use project-based pricing. All of them require one thing: scans.

This lets you defer the decision—not the preparation.

4. Scanned Logs Are the Easiest Way to Share, Sell, or Hand Off Your Airplane

When you sell an airplane, you do not hand over the originals until the transaction closes. But every serious buyer wants to see the logs early.

Scans solve this elegantly:

- You can share a complete, high-quality digital copy without risk.

- Mechanics can review your records before beginning work.

- Insurance underwriters can verify equipment and times.

- A DAR can pre-screen your history before an inspection.

- And if you ever change shops or move across the country, your logs move with you instantly.

They are the portable version of your aircraft’s biography.

5. Scanning Helps You Stay Organized Without Touching the Originals

One underappreciated advantage of scanned logs is that they let you build structure over time without physically editing your paper books.

With scanned pages you can:

- Tag entries for components (airframe/engine/prop/avionics/modifications)

- Add metadata like TT/TSO, SB applicability, dates, and costs

- Index work chronologically or by system

- Link digital “entries” to the source pages

- Build your own maintenance history map without writing in the logbooks themselves

Your paper logs stay pristine.

Your digital index gets smarter every year.

6. Scans Make Digital Dashboards Possible

The next section will go deep into the digital “thinking layer,” but the short version is this:

A smart online dashboard only works if you have scanned pages to link to.

Digital tools can:

- Track approaching inspections

- Calculate TBO intervals

- Flag recurring maintenance tasks

- Summarize component histories

- Tie events to airframe/engine/prop/avionics/rotax SBs

- Build a master record of your aircraft configuration

But the authoritative source for each event remains the scanned page of the log.

The dashboard organizes the information.

The scans prove it.

Why an Online Service Is Still Essential

If paper is the master and scanned copies are the insurance policy, the online layer is the intelligence of the system. This is where your records become useful in ways paper alone can’t achieve—especially when you’re managing both pilot and aircraft responsibilities as a single GA owner.

This isn’t about storing everything in the cloud. It’s about using digital tools to interpret, organize, and coordinate your aviation life so nothing slips through the cracks.

1. Aviation Is Full of Time-Driven Requirements You Shouldn’t Track Manually

Currency, inspections, recency, TBO intervals, upcoming tasks—paper is terrible at helping you manage any of this. Digital tools are built for it.

On the pilot side, tools like Garmin Pilot and flyGarmin can:

- Track instrument and night currency

- Calculate remaining days before expiration

- Count landings and approaches

- Auto-generate 8710/IACRA totals for checkrides

- Flag gaps or anomalies in flight history

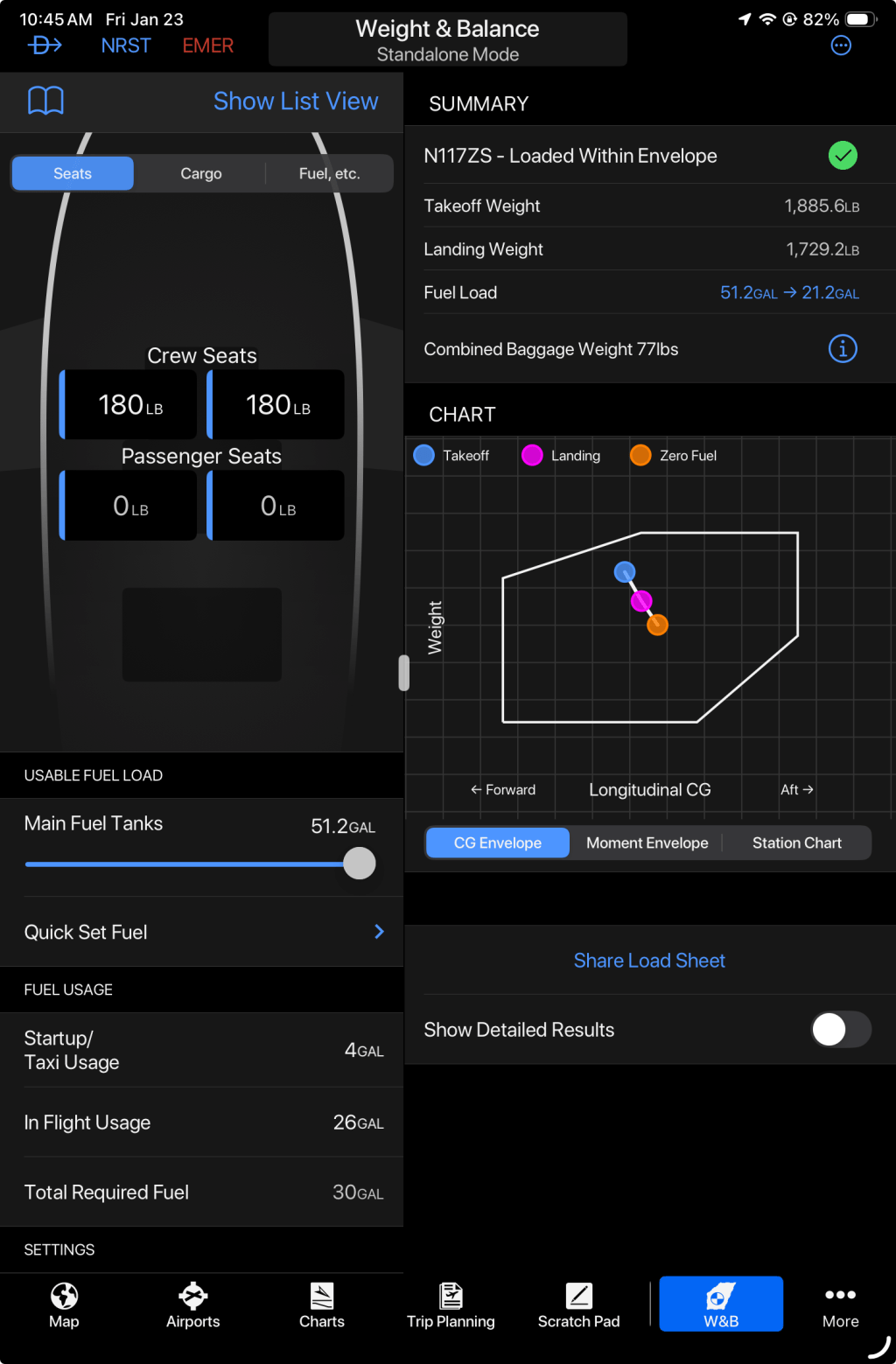

This kind of automated foresight is invaluable. For example, preparing for my instrument checkride would’ve required hours of manual log scanning without Garmin’s auto-summarized 8710 report.

On the aircraft side, the same problem appears with:

- Condition inspections

- ELT batteries

- Transponder checks

- Pitot-static tests

- Oil changes

- Propeller service intervals

- Rotax SB/SL timelines

- Component time-in-service

The best digital tools make these tasks visible, predictable, and impossible to forget.

2. A Dashboard Gives You a Single “Operational Picture” of Your Airplane

A GA pilot who owns exactly one aircraft doesn’t need an enterprise-grade fleet system. But you do need one place to see:

- Total time on airframe, engine, and prop

- Time since last major service

- Components installed (with dates)

- Upcoming requirements

- Squawks and resolutions

- Modifications

- Historical trends

- Linked scanned entries for each event

Paper can never give you this level of situational awareness.

Your brain shouldn’t be expected to do it either.

A digital dashboard does the heavy lifting and lets you fly and maintain more confidently.

3. The Online Layer Reduces Cognitive Load, Not Flexibility

One danger with all-digital approaches is lock-in: all your history, all your scanned documents, all your metadata—everything trapped inside one company’s interface.

Your model avoids that entirely:

- The online service stores only key metadata (dates, times, component labels, intervals).

- The authoritative record lives in your scanned PDFs and paper books.

- You can export the metadata anytime.

- The scanned logs are platform-independent.

- The dashboard becomes replaceable, just like an EFB or checklist app.

The online layer becomes a tool, not a dependency.

You’re using technology for its strengths—not asking it to do things it can’t guarantee over decades.

4. This Layer Is Where Modern Flying Actually Happens

Today’s GA pilot relies on digital workflows:

- EFB flight logs

- Auto-imported GPS tracks

- Weather briefings

- Weight-and-balance modeling

- IFR routing suggestions

- Currency calculators

- Performance tables

- Maintenance reminders

- SB/SL/AD monitoring

- Reservation or scheduling (for shared aircraft)

- Oil, fuel, or trend tracking (where applicable)

This is the modern cockpit.

It’s not optional—it’s simply how aviation works now.

But none of these tools are designed to be permanent archives. They’re meant to interpret, not preserve. That’s why your digital layer plays the real-time role in the system.

Paper holds the history.

Scans keep it resilient.

Digital keeps it smart.

5. Experimental Aircraft Make This Layer Even More Valuable

Unlike certified aircraft, experimentals:

- Don’t fit neatly into AD databases

- Use components from varied suppliers

- Accumulate custom modifications

- Require owner-specific maintenance planning

- Follow SLs and SBs differently

- Need more personalized tracking

Most standardized digital platforms struggle with this variability.

Your model fixes it because the online layer doesn’t attempt to ingest your entire log history or apply certified-world assumptions. Instead, it manages:

- Reminders

- Intervals

- Events

- Components

- Personal checklists

- Configurations

- Links to the real log entries

This is the level of organization that experimental owners actually need.

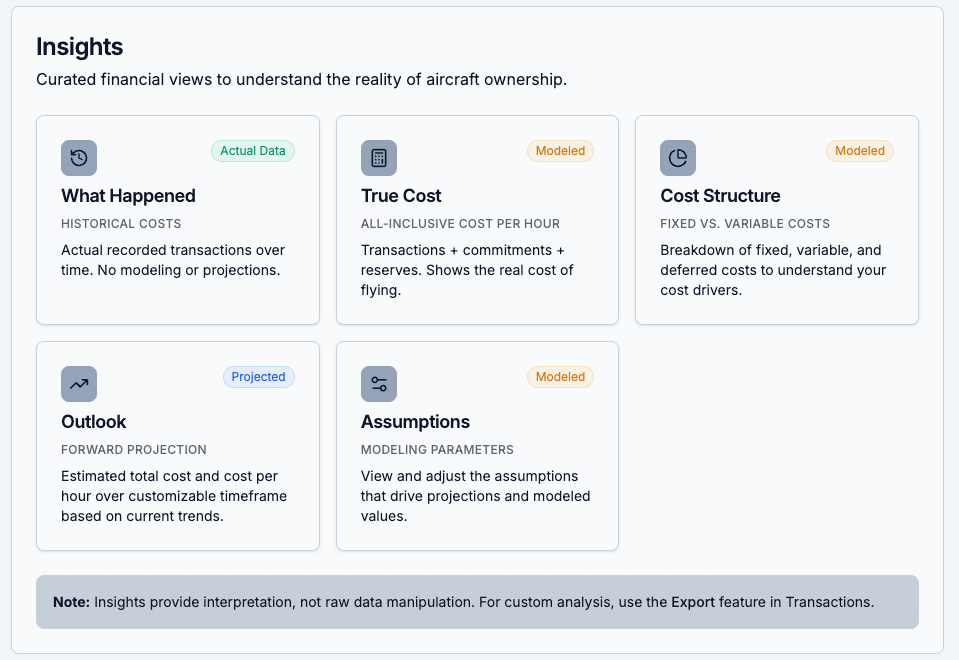

6. The Online Layer Makes Your Data Actionable, Not Just Archivable

Paper preserves.

Scans protect.

Digital guides.

The online service is where you turn raw records into:

- Next steps

- Due dates

- Risk mitigation

- Insights

- Summaries

- Planning

- Quick decision-making

- Everyday operational readiness

It’s the part of the system that helps you be a better, safer, more organized pilot.

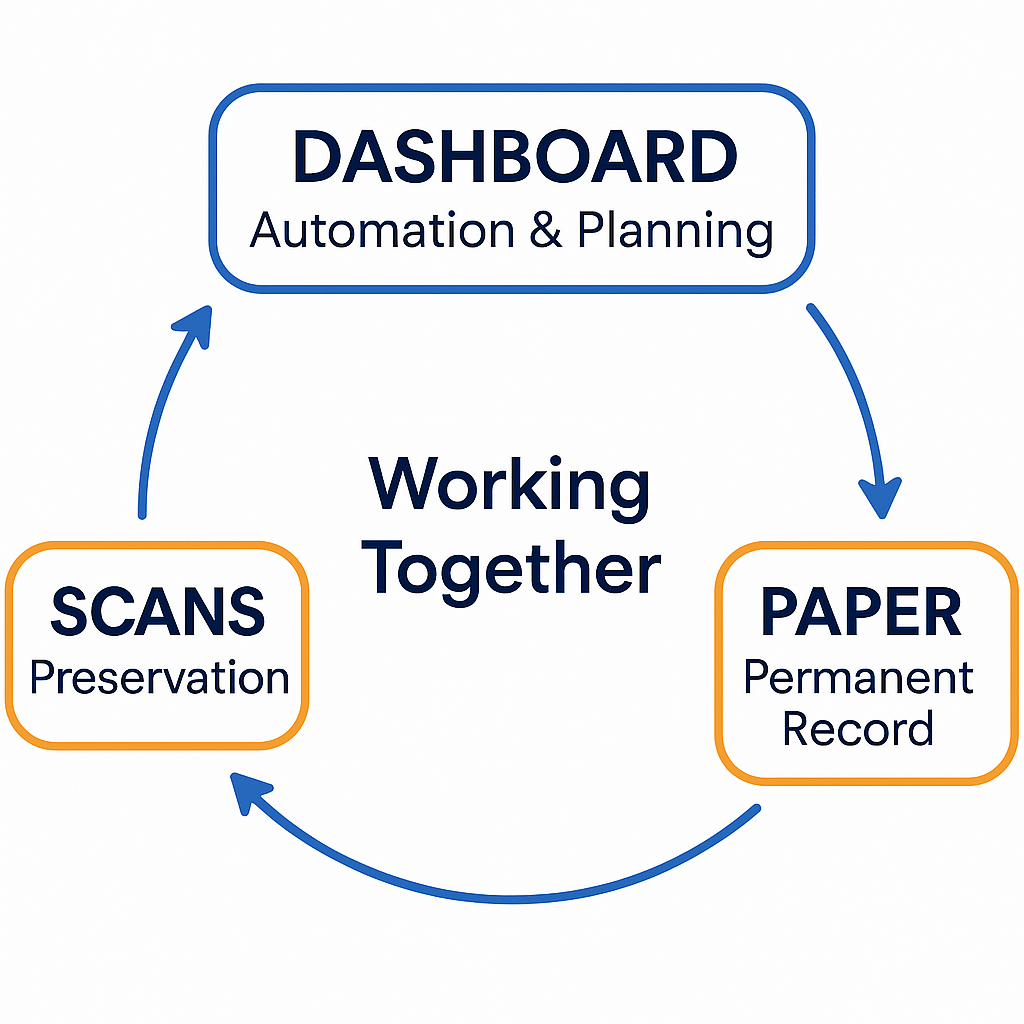

The Online Layer Is the Brain—Not the Vault

When used correctly, digital tools provide extraordinary value:

- Awareness

- Forecasting

- Organization

- Automation

- Integration

But they should never be the single source of truth.

Your model uses them for what they excel at, while keeping your long-term history safe in formats that outlast the tech landscape.

Why This Hybrid Model Wins (Summary Table)

| Benefit | What It Means for a GA Pilot/Owner | Why It Matters |

|---|---|---|

| Low Cost | Uses simple paper logs, basic scanning, and a lightweight digital layer. | Avoids decades of subscription fees required by full digital record systems. |

| You Control Your Data | Paper and scans remain in your custody; the online layer stores only metadata. | No dependence on any one vendor or platform for the preservation of your history. |

| Easy to Share | Scanned PDFs can be emailed to mechanics, buyers, insurers, or DARs. | Eliminates the risk of mailing original logs and speeds up collaboration. |

| Minimal Lock-In | The dashboard is portable: exportable, replaceable, and not tied to proprietary formats. | Prevents painful migrations if a service shuts down or changes pricing. |

| Adapts as Your Needs Change | You can switch EFBs, upgrade tools, or digitize later without restructuring your archive. | Supports decades of evolving pilot and aircraft requirements. |

| Best Tool for Each Job | Paper = permanent record; scans = preservation; dashboard = automation and planning. | A balanced system that stays simple while leveraging the strengths of each layer. |

| Lower Cognitive Load | The digital layer tracks deadlines, intervals, and trends so you don’t have to. | Reduces mental workload and increases confidence in staying compliant. |

| Future-Proof | Paper and scans survive tech churn; digital tools can be swapped anytime. | A long-term solution that matches aviation’s multi-decade timeline. |

| Peace of Mind | Your records are safe, redundant, and organized across three layers. | You fly and maintain your airplane without the lingering fear of losing history. |

How I Use This Model for My Pilot Logs

I started building this system with my pilot logbook, long before applying it to aircraft maintenance. The idea was straightforward: the paper log remains the official, long-term master, and anything that requires ink—endorsements, checkride signoffs, BFR/IPC entries—lives only there. But the moment a page fills up, I scan it. Every flight page, every signature page—anything I would not want to lose—gets turned into a clean PDF and stored in a simple folder structure. It’s not for analysis; it’s just insurance. If the physical book ever gets lost, soaked, borrowed, or buried under a pile of sectional charts, the irreplaceable history is still intact.

For the day-to-day flying, Garmin Pilot does the heavy lifting. It logs every flight automatically—times, approaches, night landings—and keeps all the currency calculations up to date. flyGarmin gives me the form 8710 totals that saved me a pile of manual work during instrument training. And for richer post-flight analysis, I export my flight traces from Garmin Pilot and upload them to FlySto. That combination gives me a complete picture: Garmin Pilot for day-to-day tracking and compliance, FlySto for the deeper analytics and the fun “what really happened on that approach?” moments. But none of these tools replace the paper logbook; they’re the “thinking layer,” not the archive.

This hybrid setup—paper as the master, scans as protection, digital tools for intelligence—has worked so naturally for my pilot records that it became the blueprint for how I now manage my aircraft logs. The model scales perfectly: keep the official history on paper, protect it with scans, and let technology handle everything that benefits from automation, reminders, or deeper insight.

The Missing Piece (and What I’m Working On)

If the hybrid model works beautifully for pilot logs, it should work just as well for aircraft maintenance records—at least in theory. The challenge is that most existing digital maintenance platforms aren’t designed around this philosophy at all. They want to be the archive, not the analysis layer. And that creates a problem for single-aircraft GA owners.

Services like Bluetail, PlaneLogix, and Coflyt are built around the assumption that your entire maintenance history will live inside their system: every scanned page, every log entry, every document, every invoice, every SB, every compliance note. They offer powerful features—cloud backups, component tracking, smart search, AI tagging—but they also require full ingestion of your logs into their ecosystem. For fleets, corporate departments, or Part 135 operators, this makes sense. For an individual experimental owner, it’s overkill, expensive, and—most importantly—not aligned with the “paper master + scanned backup” structure.

What’s missing is a tool designed around the owner-centric version of the hybrid model:

- A system that doesn’t require you to upload your entire logbook archive.

- A system that stores metadata, not every maintenance log entry.

- A system that links to your scanned PDFs rather than absorbing them.

- A system that skews towards the simplicity of managing of a single aircraft, not a fleet.

- A system that tracks intervals, components, SB/SLs, and reminders without automation requiring a overly regulated and structured framework .

- A system that is light, portable, owner-controlled, and future-proof.

In other words: a dashboard that acts as the brain, not the vault.

This is the piece that doesn’t really exist today. The certified-world tools are too heavy and too dependent on pulling everything into their environment. Spreadsheet approaches are too fragile. And nothing in the experimental world strikes the right balance between structure and freedom.

So… I’m working on something. Something small. Something owner-focused. Something that respects the hybrid model rather than fighting it. I’m not ready to share details yet, but the goal is simple: a clean, intuitive, low-friction way to manage your aircraft’s operational picture without surrendering your history to a third-party platform.

More to come soon.

Leave a comment