When I started this build, my goal wasn’t just to put together a capable airplane — I wanted to build a modern airplane. Something that reflects where general aviation should be headed: FADEC engine, glass cockpit, smart avionics, and yes, a propeller that doesn’t rely on oil lines, governors, and a 1940s-era blue knob. That’s why the Airmaster electric constant-speed propeller caught my attention early on. It’s elegant, automated, and purpose-built for the kind of pilot experience I’m after — one where I focus on flying the mission, not fiddling with knobs. When I learned that Airmaster now offers a prop specifically for the Rotax 916iS, it felt like the missing piece had finally shown up on the table. There’s just one final hurdle: Sling still needs to approve it for use on my build. So now, I wait — excited, hopeful, and very ready to ditch the hydraulic plumbing for good.

When I ordered my Sling TSi, I had a choice between two excellent engines: the Rotax 915iS and the newer, slightly more powerful 916iS. While the 916iS offered a better TBO (2,000 vs. 1,200 hours), more power (160HP vs. 141HP), and seemed like the obvious modern choice, there was one frustrating catch: the propeller.

But here was the rub: at the time of my order, Airmaster didn’t yet have a propeller rated for the 916iS’s extra power. That meant Sling’s only option was to pair it with the MT-34, a traditional hydraulic prop that, while reliable, felt like a step backward. I genuinely considered dropping down to the 915iS just to keep the Airmaster.

Ultimately, the longer TBO of the 916iS sealed the deal for me. Still, it stung… until recently.

I found out that Airmaster quietly released a new model—the AP431HCTF-WWR72B—designed specifically for the 916iS. Even better, a builder at Sling’s own build-assist center in Torrance was already installing it. I reached out to The Airplane Factory, and they confirmed they were evaluating the new prop’s performance. If it works well, they’ll swap my MT order for the Airmaster.

So now, I wait — and in the next section, I’ll walk through the deep-dive comparison between these two propeller systems: one electric, one hydraulic, and what each means for performance, usability, and maintenance.

MT vs. Airmaster: A Propeller Comparison for the Sling TSi

For those who want to get nerdy with every blade angle and servo detail, I’ve prepared a full deep-dive paper comparing the two constant-speed propeller options available for the Rotax 916iS: the MT hydraulic propeller (the current factory standard) and the Airmaster electric propeller (newly available for the 916iS). You can download the full document here:

But if you want the executive summary with just enough detail to make a confident decision, here’s a streamlined breakdown across key categories:

Materials: Construction Matters

The materials each propeller uses tell a lot about their design philosophy. The MT propeller blades are built with a wooden core surrounded by a carbon fiber and fiberglass composite shell, plus nickel alloy leading edges for erosion protection. This construction makes the blades relatively light, strong, and excellent at damping vibration—one reason MT props are famous for smoothness.

The Airmaster system (specifically the AP431 series hub) pairs an aluminum and steel hub with WhirlWind carbon-fiber composite blades. These blades are true carbon fiber throughout (not wood core), with similarly durable nickel leading edges for erosion resistance. This results in slightly stiffer, more durable blades under heavy loads or harsh conditions.

In short, MT offers a traditional hybrid approach (wood core for vibration absorption), while Airmaster/WhirlWind goes fully modern with pure carbon-fiber blades aimed at maximizing strength-to-weight ratio.

Control: Hands-On vs Push-Button

The MT prop uses the traditional “blue knob” linked to a hydraulic governor—push it forward for high RPM (fine pitch), pull it back for cruise. This setup gives you full manual control and tactile feedback, similar to legacy constant-speed GA aircraft. It’s a well-known system with a short learning curve for most pilots.

The Airmaster replaces that knob with an electronic controller offering preset modes like Takeoff, Climb, Cruise, and Feather. Turn a knob, and the prop adjusts pitch automatically to maintain the desired RPM. The automation reduces pilot workload and makes the aircraft feel like it has a single-lever power control system—ideal for pilots who fly IFR or just don’t want to fiddle with knobs.

MT gives you full authority and direct control; Airmaster gives you modern, intuitive automation.

Weight: Every Pound Has a Purpose

The MT prop system (including spinner and governor) weighs around 24–25 lbs, while the Airmaster setup (hub, blades, spinner, and motor) comes in at about 31 lbs. That’s a 6–7 lb increase with the Airmaster — not trivial on a light aircraft, but not disqualifying either.

Now here’s the twist: while we usually think “lighter is better,” the Sling TSi actually has a known aft CG tendency, particularly when flying low on fuel near the end of a long flight. In this context, the extra forward weight of the Airmaster can actually help balance the aircraft, shifting the CG forward toward the center of the envelope. That gives you a little more flexibility in loading passengers and bags without needing to worry about creeping too far aft.

Yes, the added weight does eat into your total useful load — a consideration on long trips — but in many flight scenarios, that weight improves the plane’s balance.

MT is lighter and maximizes useful load; Airmaster adds a few pounds up front, but it can help tame the Sling’s rearward CG tendencies.

Installation: Wrenches vs. Wiring

Installing the MT means dealing with a hydraulic governor, oil lines, safety wiring, and cockpit linkage. It’s a few extra steps but manageable, especially for experienced builders or with factory assist.

The Airmaster is a cleaner install: no oil plumbing, no governors—just bolt the prop, run the electrical harness, and mount the controller. Airmaster includes well-documented install kits, making this about as plug-and-play as experimental aircraft get.

MT takes more mechanical setup; Airmaster is a faster, simpler install—especially DIY-friendly.

Maintenance: Oil Seals vs Grease Guns

The MT requires little ongoing maintenance aside from occasional inspections and a long-term overhaul around 1500–2000 hours. But it’s hydraulic, so oil leaks can happen, and fixing those usually means removing the prop.

The Airmaster has no oil system to worry about but does require annual greasing of the blade hubs—about an hour’s work. Overhaul is due at 2,000 hours, and because the prop is modular, some repairs can be handled without removing the whole unit.

MT is lower maintenance in the short term but potentially messier if issues arise; Airmaster is cleaner and owner-serviceable, but requires regular attention.

Performance: No Wrong Answer Here

In terms of climb rate, cruise speed, and fuel efficiency, both props deliver excellent results when properly tuned. Pilots have reported near-identical numbers—around 1,200 fpm climb and 158 KTAS cruise at altitude—regardless of which system is installed.

MT and Airmaster are equals in performance. The difference isn’t in thrust; it’s in how you get there.

Emergency Behavior: Fail-Safe Philosophy

The MT prop typically goes to coarse pitch (or feather-like) if oil pressure is lost, which can reduce drag and help in a power-off glide.

The Airmaster, on the other hand, holds its last commanded pitch if electrical power is lost, behaving like a fixed-pitch prop. It also supports full feathering via a dedicated switch—potentially useful in certain emergencies or for ground testing.

MT relies on hydraulic failsafe design; Airmaster uses electronic fail-hold logic with a pilot-commanded feather option.

Support & Service: Network vs Niche

MT Propeller has a broad support network, especially in North America and Europe. Many certified aircraft use MT props, so parts and service are widely available.

Airmaster is based in New Zealand, and while they have excellent customer service and some U.S. distributors, major service or overhaul usually means shipping back to the factory. For most owners, this won’t be an issue until the 2,000-hour mark—but it’s worth noting.

MT wins on service availability and turnaround time; Airmaster is smaller-scale but responsive and modular.

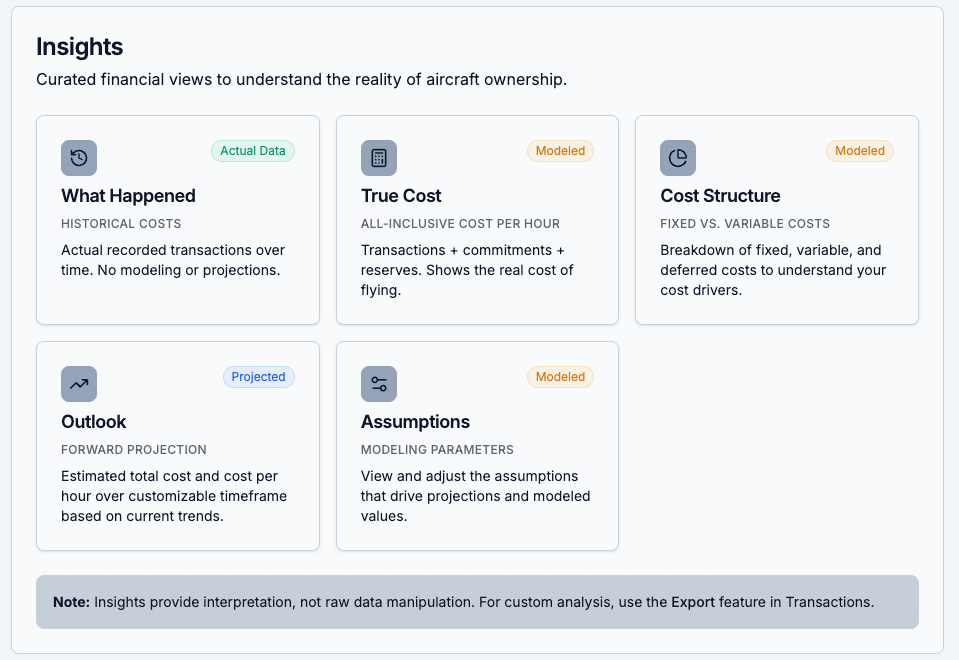

Summary Comparison Table

| Category | MT Propeller (Hydraulic) | Airmaster Propeller (Electric) |

|---|---|---|

| Control | Manual prop lever (“blue knob”) | Turn knob with presets |

| Materials | Wood-core blades, carbon/fiberglass skin, nickel leading edge | Full carbon-fiber blades, nickel leading edge |

| Installation | Involves governor, oil lines, and mechanical linkage | Simplified electrical install; no oil plumbing |

| Maintenance | Low short-term; overhaul ~1500–2000h; watch for oil leaks | Annual blade greasing; overhaul at 2000h; no oil issues |

| Weight | ~24–25 lbs (lighter) | ~31 lbs (heavier by ~6–7 lbs) |

| Performance | Excellent, factory-validated | Equivalent real-world results |

| Emergency Behavior | Springs to coarse pitch on oil loss | Holds last commanded pitch; supports feathering |

| Support | Extensive network, U.S. service centers | Smaller network, good support, centralized overhaul |

| Ease of Use | Traditional; hands-on engine management | Low workload; FADEC-style “just fly it” simplicity |

Here’s a good closing section for your blog post, tying everything together with your personal story and excitement:

Closing Thoughts: A Modern Sling, Waiting on the Final Piece

Summing it up: both the MT hydraulic and Airmaster electric constant-speed propellers are excellent choices for the Sling TSi with the Rotax 916iS. They deliver almost identical performance in climb and cruise. The differences come down to philosophy: MT leans on traditional, direct pilot control with a lighter installation, while Airmaster embraces modern automation, reduced workload, and a sleek pilot interface.

For me, the choice was always about building a modern airplane—one that feels as advanced in its systems as it is in its performance. That’s why I was genuinely disappointed when, at the time of my engine order, the Airmaster option wasn’t yet available for the 916iS. I almost considered downgrading to the 915iS just to keep the electric propeller.

Fortunately, that story has a new chapter.

With the release of the Airmaster AP431HCTF-WWR72C, specifically engineered to handle the 160 horsepower of the 916iS, the dream is back on track. Even more exciting, a builder is already installing this prop at the Airplane Factory’s build assist center in Torrance, and the team there is actively evaluating its performance.

Right now, I’m in a bit of a holding pattern—waiting eagerly for the Airplane Factory’s feedback on how the Airmaster performs with the 916iS in real-world conditions. If the results are positive, they have agreed to update my order, replacing the MT propeller with the Airmaster.

It feels like the final piece of the puzzle is almost in place—and I can’t wait to complete the vision of a truly next-generation Sling TSi.

Leave a comment