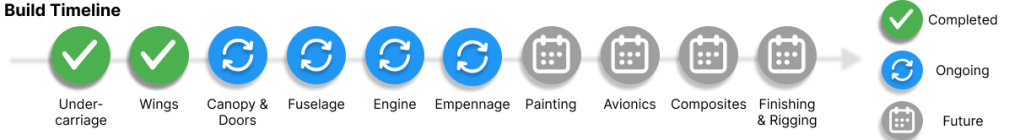

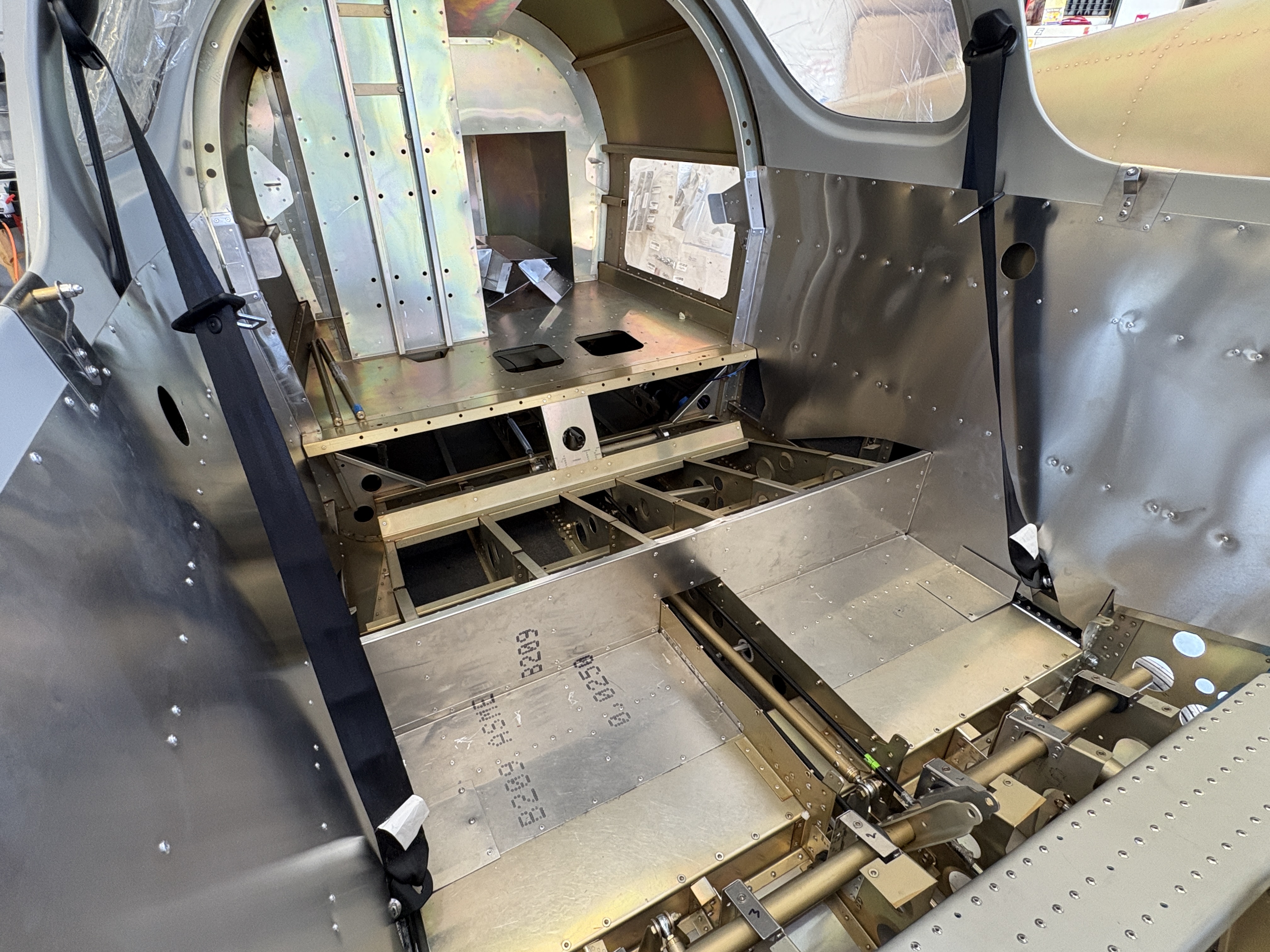

It’s been a week since my last visit to Torrance, and the team has been busy! The fuselage and firewall-forward areas are really starting to look like a finished airplane. There are now more oil and cooling hoses snaking their way around the Rotax 916iS, and much of the plumbing we worked on during the past few sessions has been finalized.

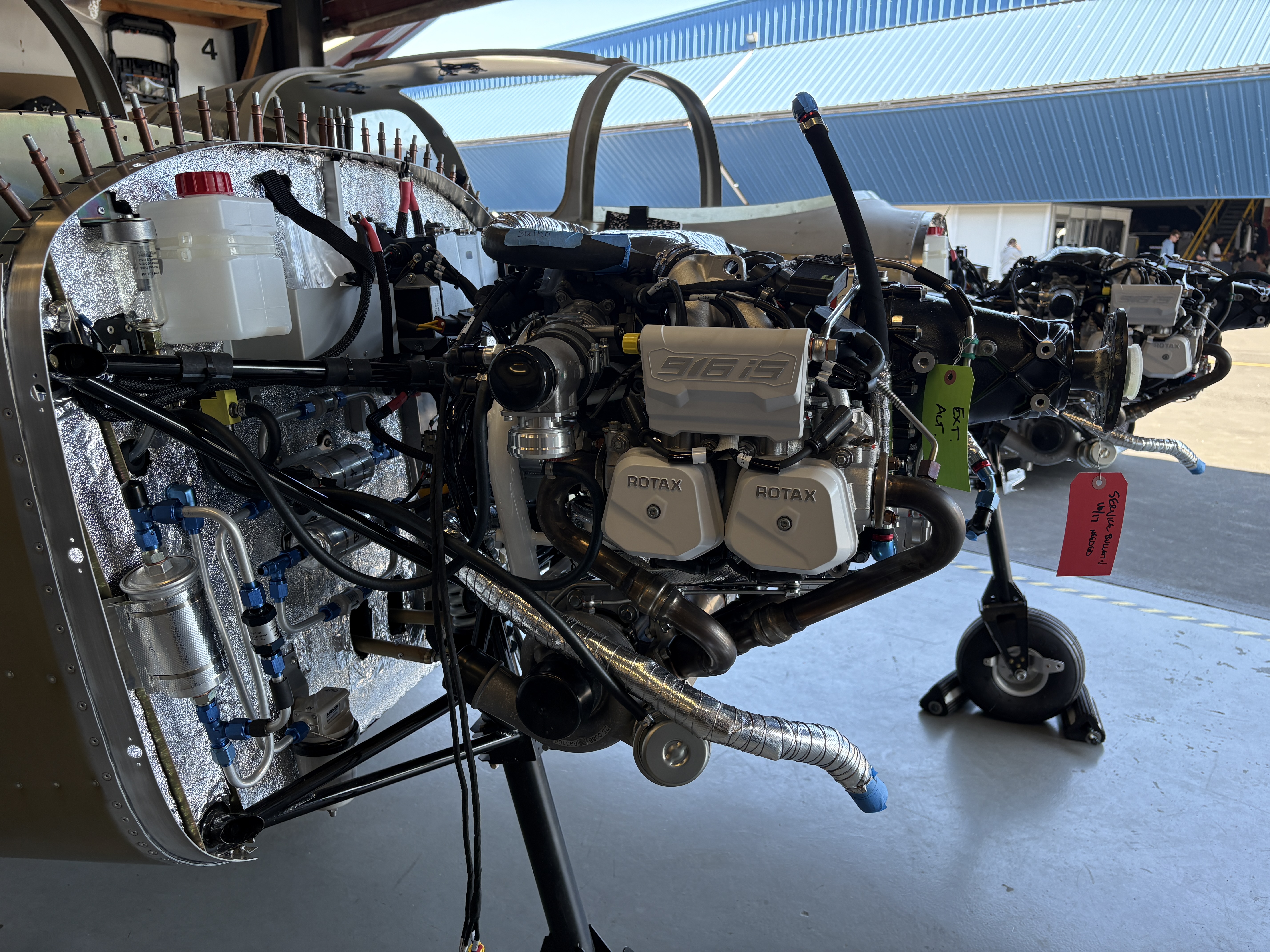

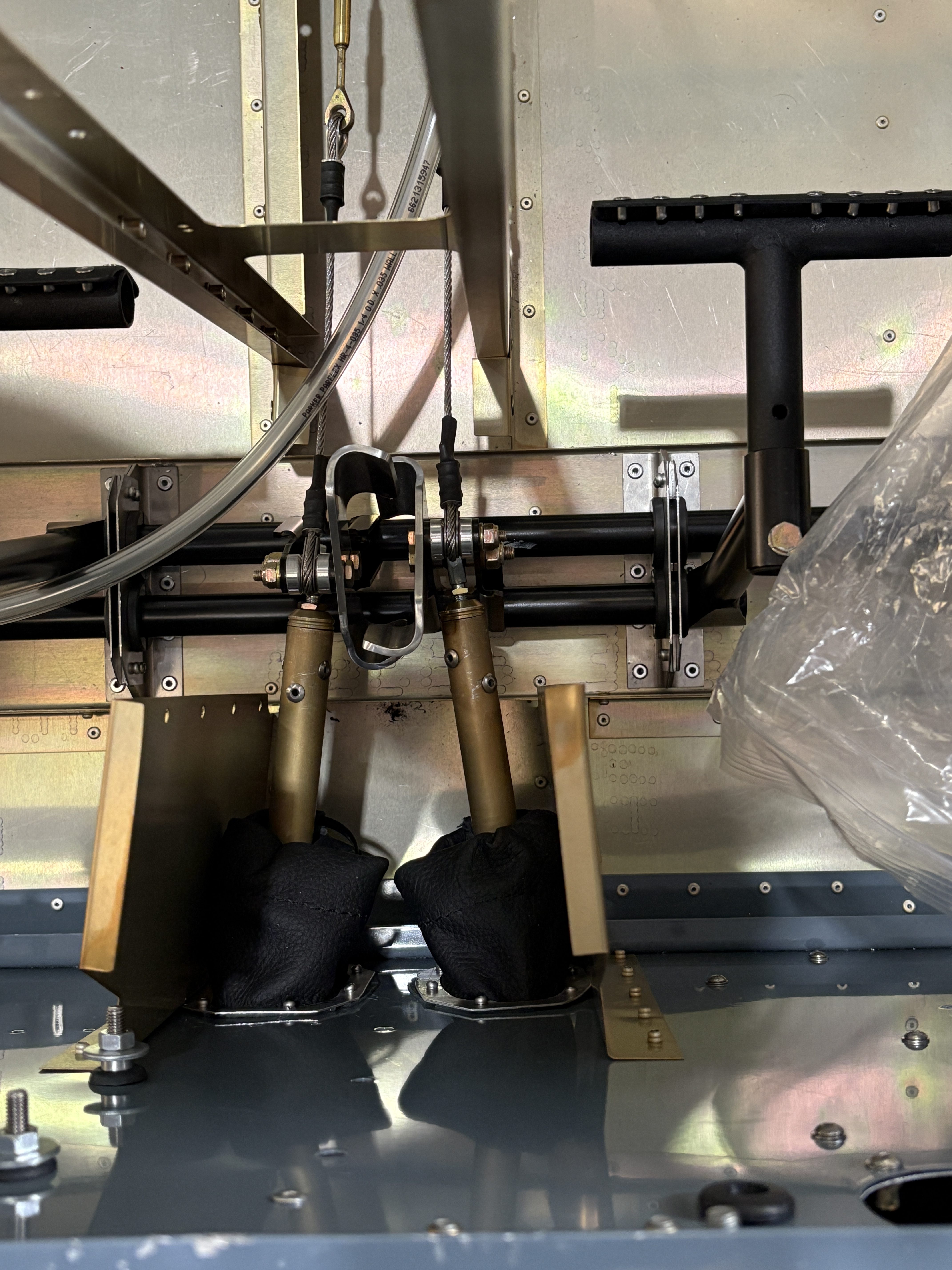

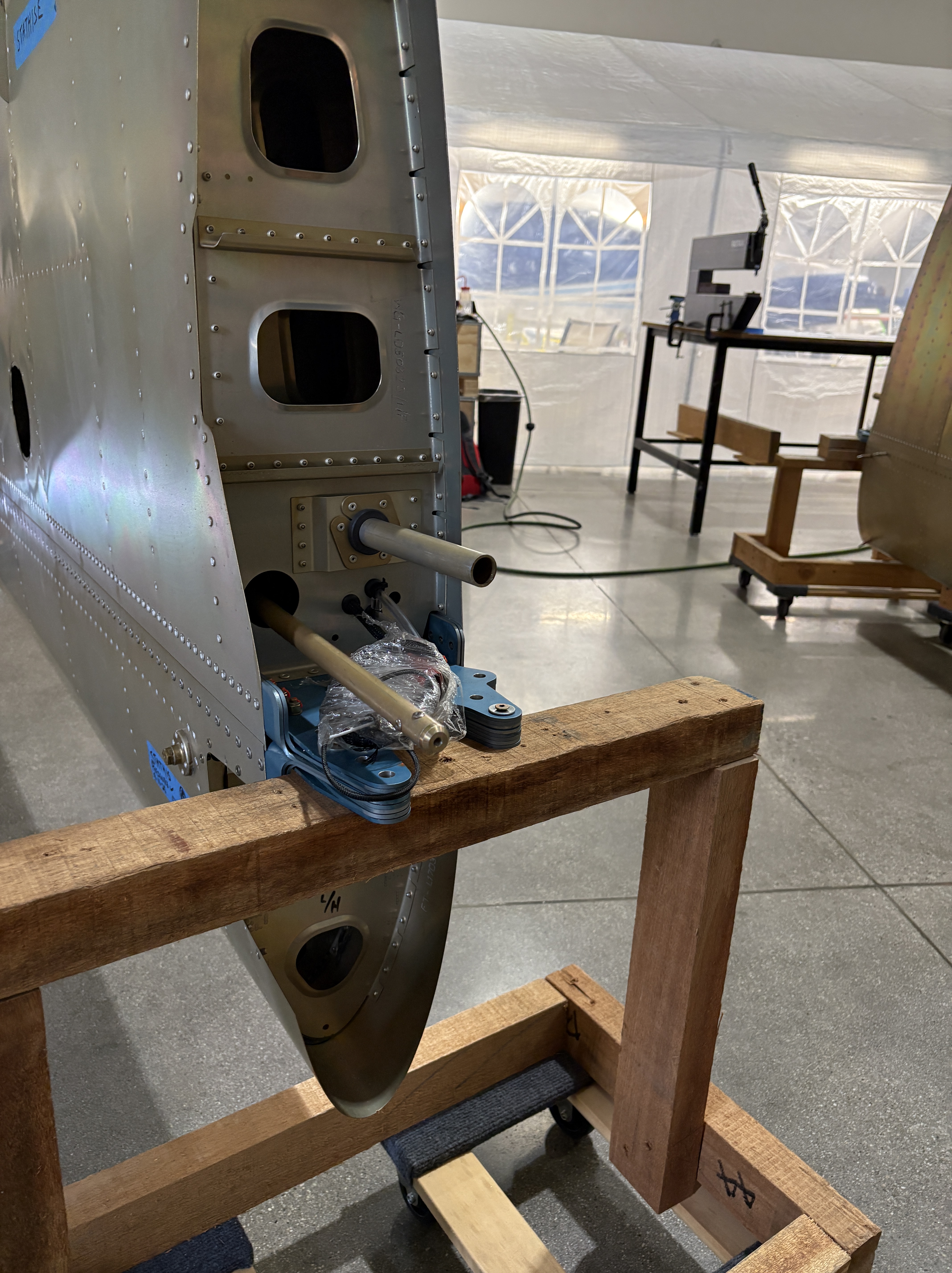

Inside the cockpit, the control sticks are now connected to the pushrods and rudder cables—so while there are no control surfaces attached yet, you can see the intricate dance of sticks, rods, and cables moving in sync. The gull-wing door mechanisms are also coming together, and the floor panels that sit over the underlying structure—covering the brake lines, pushrods, and control linkages—are now being installed. Bit by bit, the cockpit is starting to look like a real flight deck rather than a skeletal frame.

Wing Completion

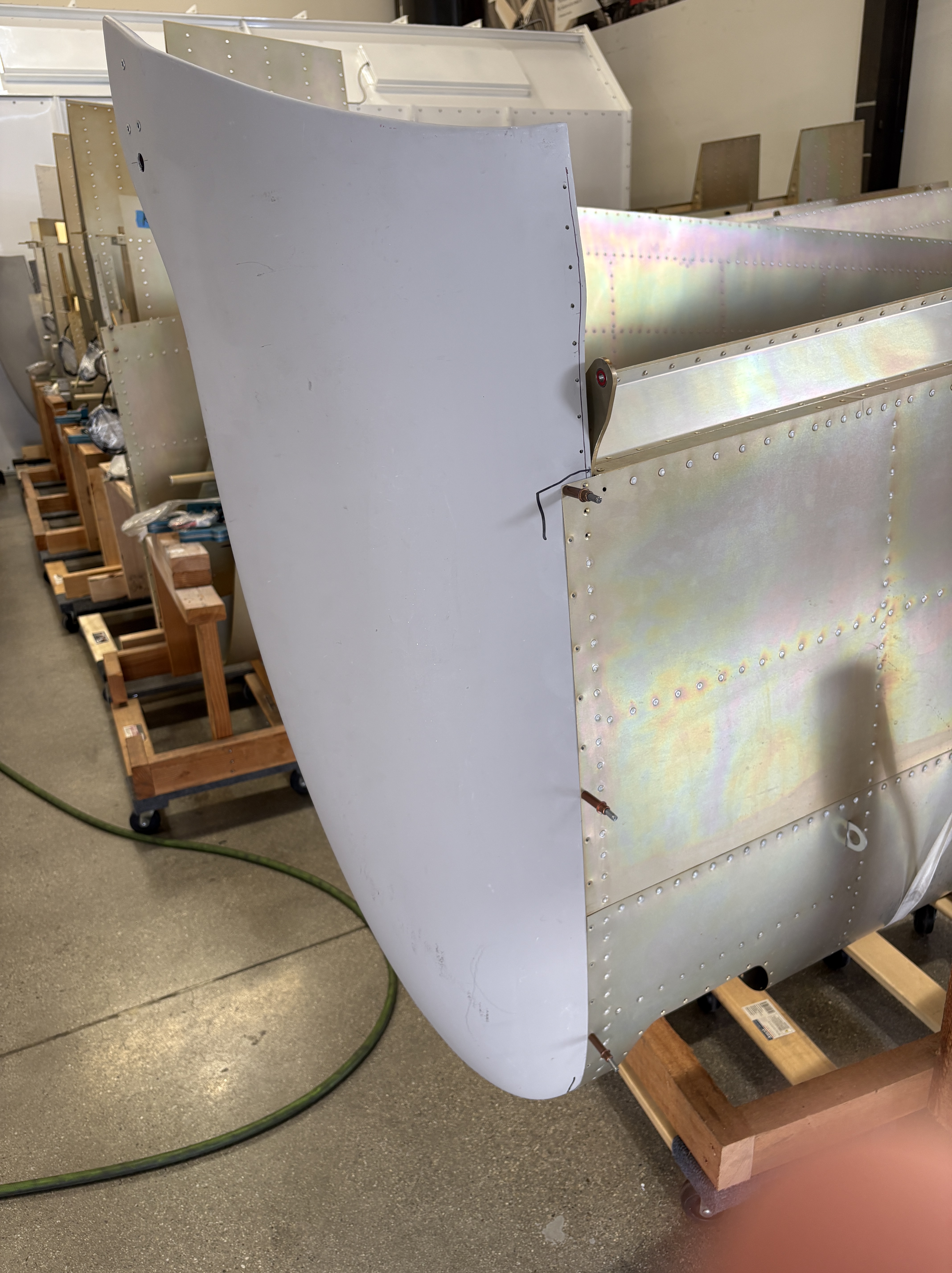

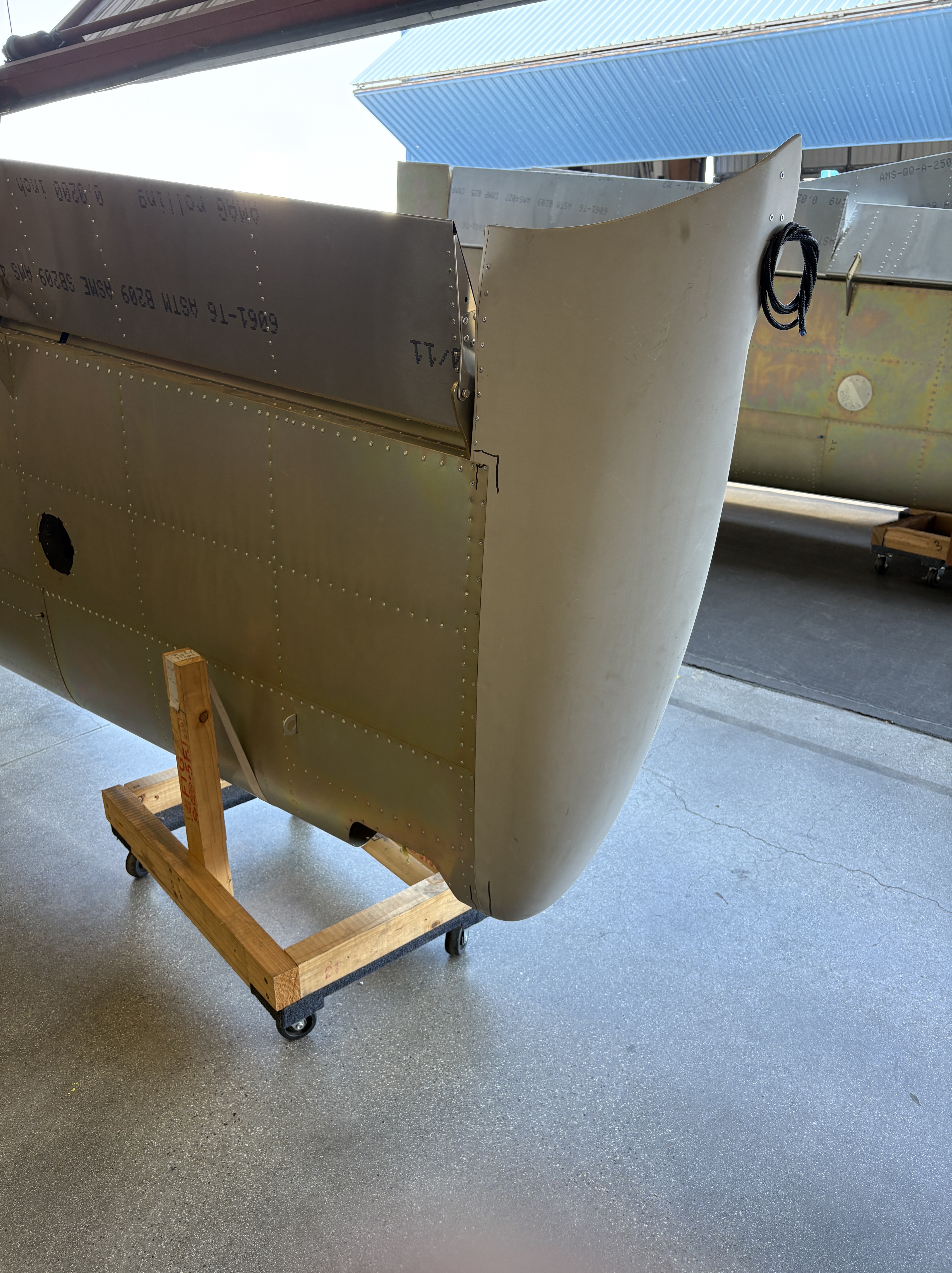

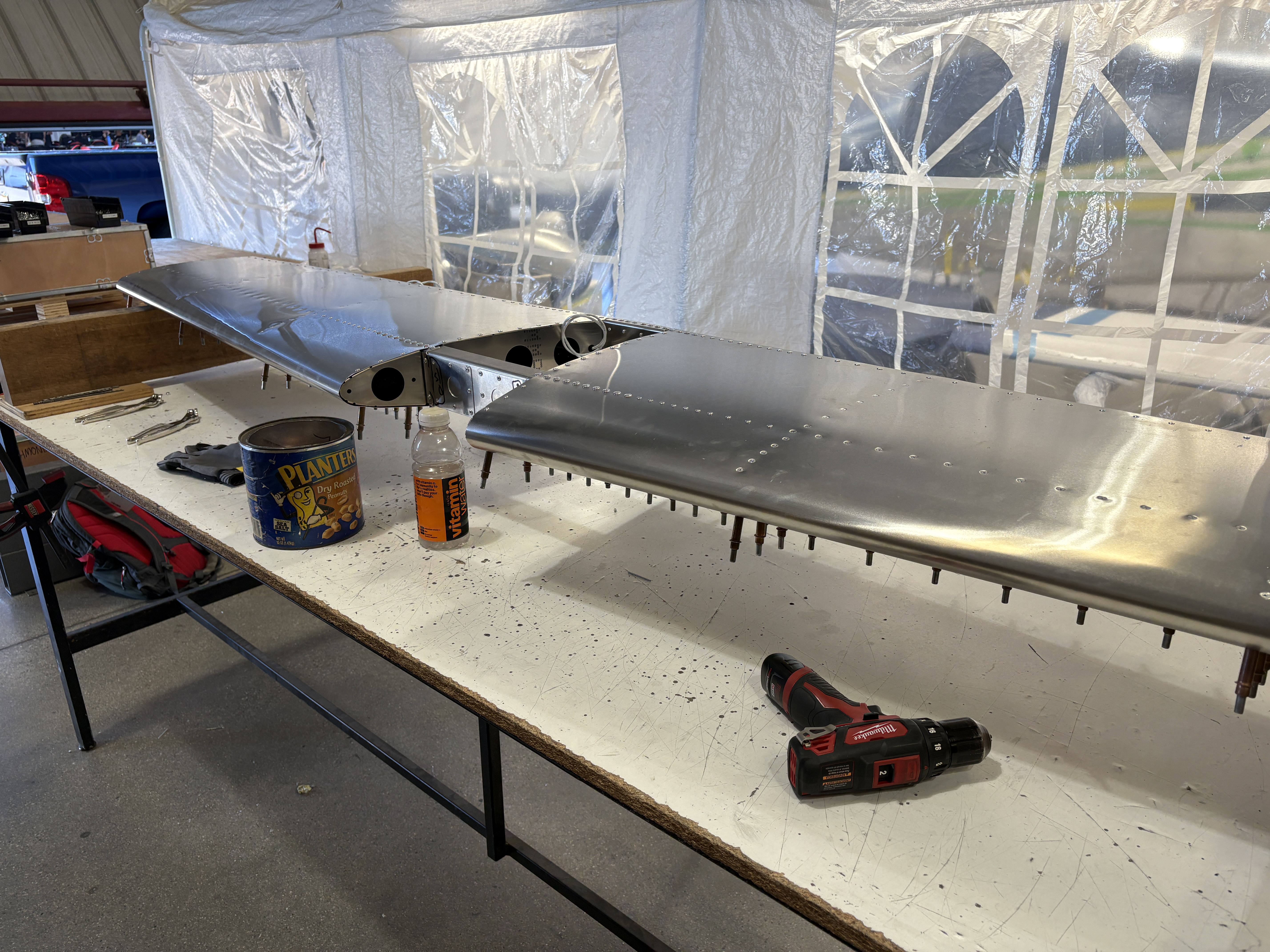

This trip’s headline: the wings are done! By the end of my visit, both wings were completed and officially ready to go for painting. That’s a major milestone—it’s hard not to grin when you see the full wings sitting side by side, ready for the next chapter.

We started by attaching the composite winglets to the main wing structure. It’s a delicate operation: trimming the edges, carefully riveting them into place, and threading the wiring that powers the position and strobe LEDs through the wingtips.

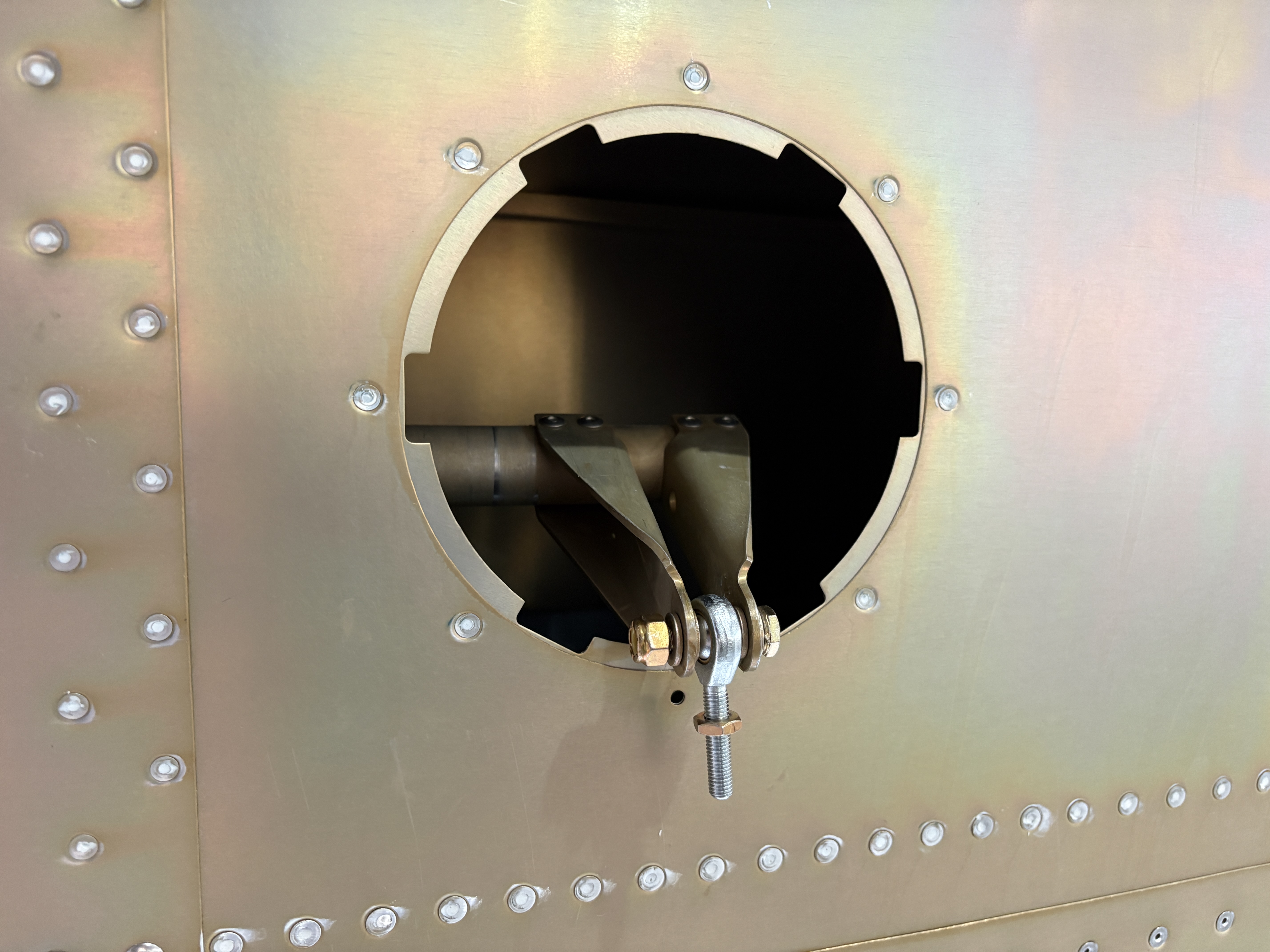

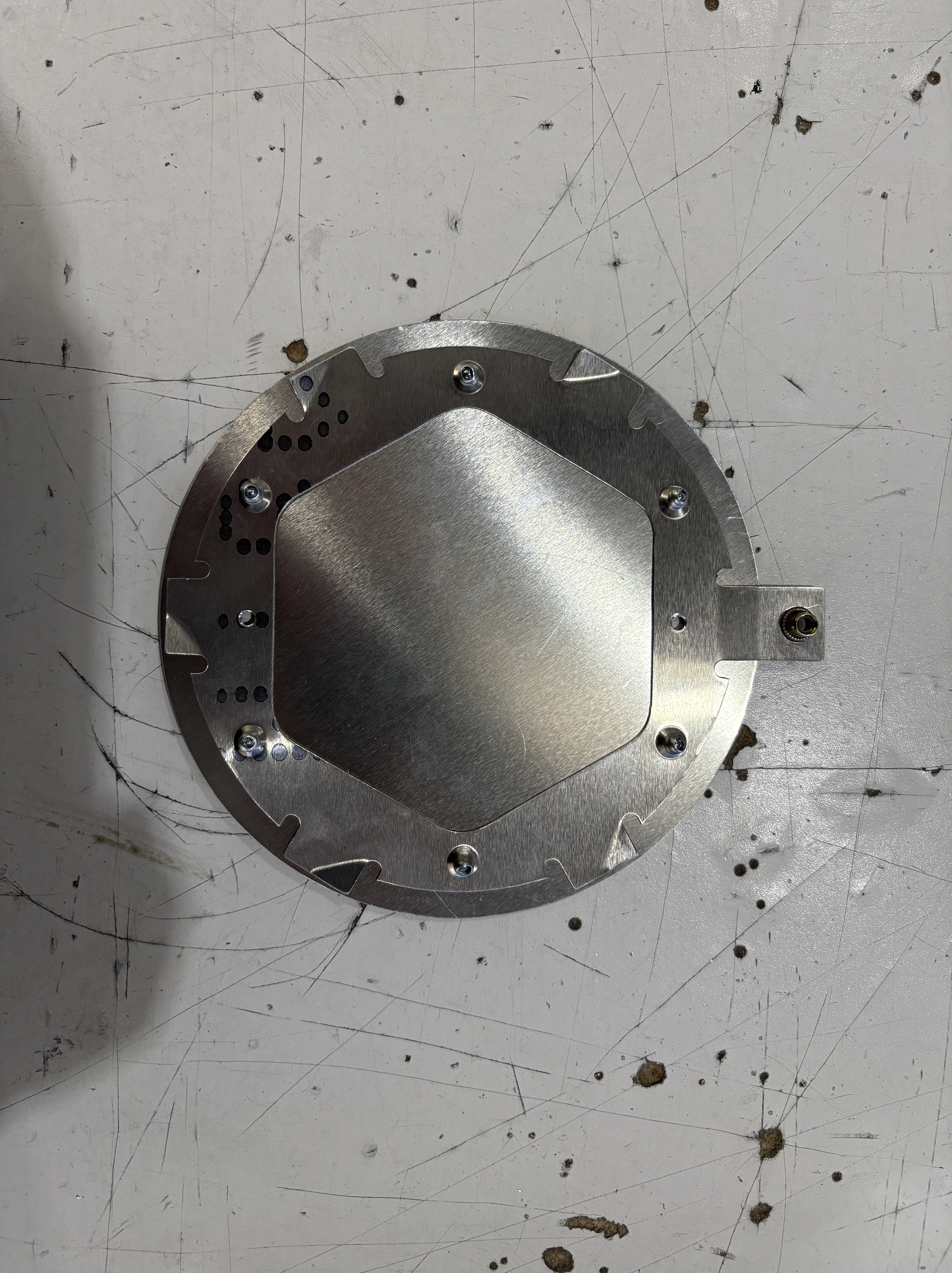

Next up were the inspection hatch covers—five in total, split between both wings. Sling’s design here is refreshingly simple and clever: each hatch twists into place and locks down with a single screw. I like these little touches that make maintenance easier later on.

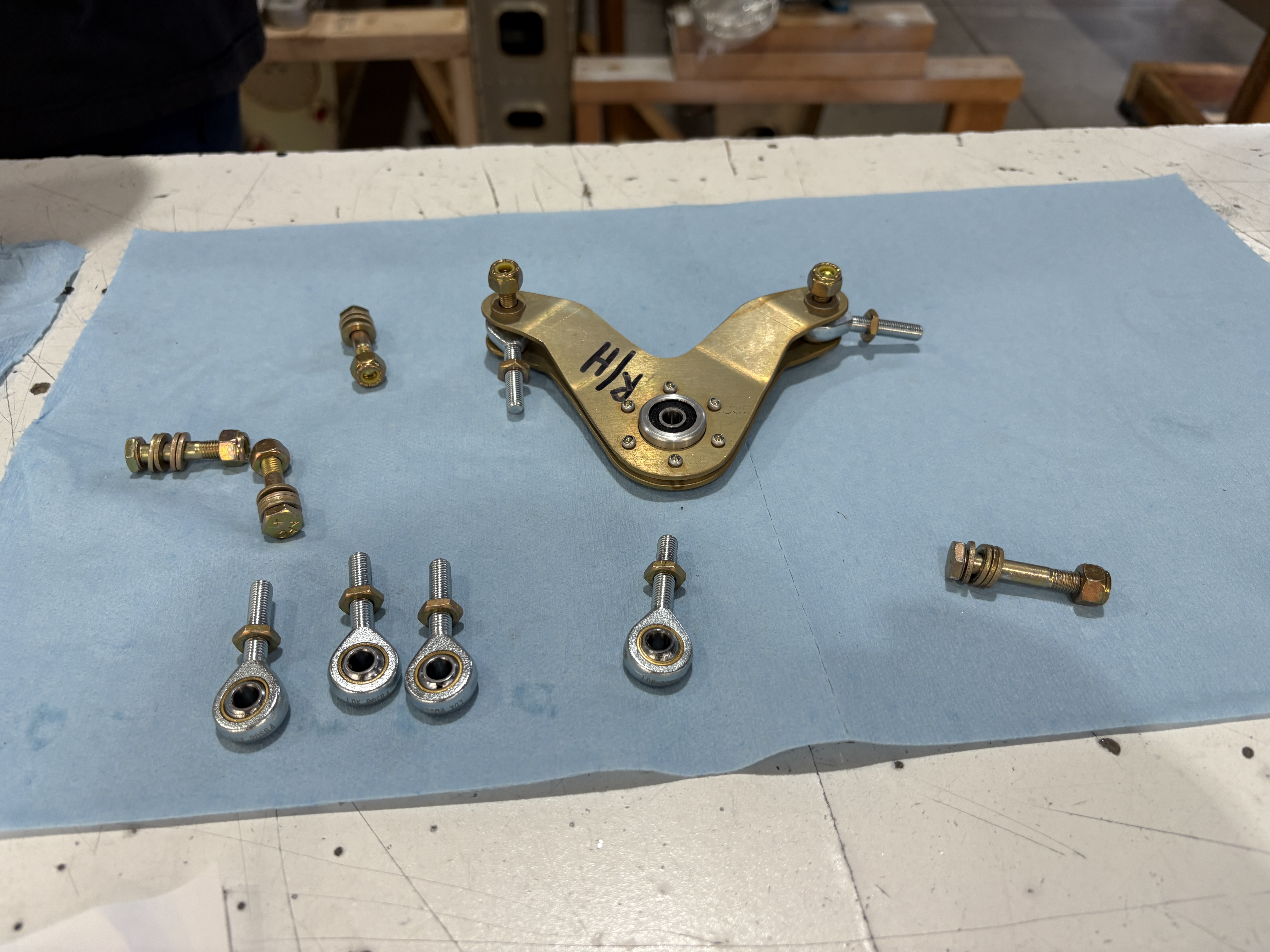

Finally, we installed the pushrod assemblies and hinges that control the ailerons. It’s the kind of work that’s both mechanical and satisfying—each linkage and rivet adding one more piece of functionality.

But not everything was straightforward. We ran into some oil canning on one of the flap skins. After inspecting and comparing with other aircraft, we found that the hinges were properly aligned, which points to a small manufacturing variance in the flap structure and skin predrilled holes. Sling confirmed it’s not a structural or safety concern, but to reduce the visual effect, one of the flap skins was replaced and refitted. Hopefully this won’t be an issue down the road, but it’s a reminder that even with factory-assist kits, aircraft building remains craftsmanship.

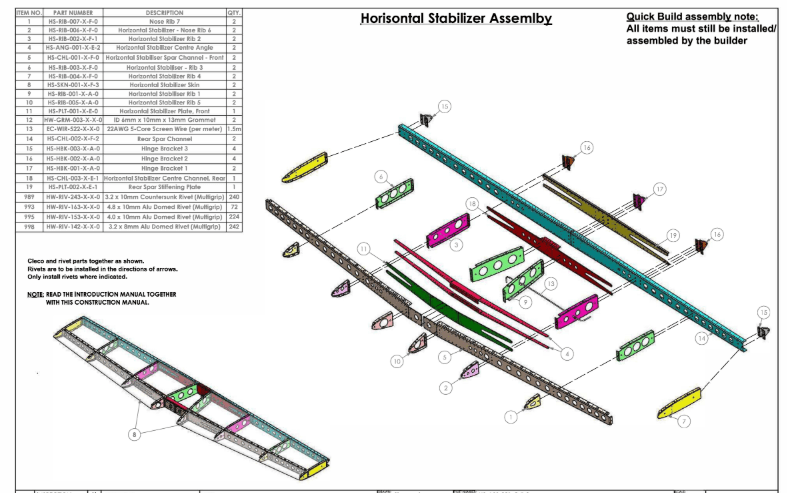

Empennage: Horizontal Stabilizer

With the wings complete, I moved on to my next challenge—the horizontal stabilizer, a large structure that demanded a lot of time and patience. I spent nearly four hours just picking the right parts from the crate, cataloging them, and removing the stubborn plastic protective film from each piece. It’s actually the biggest structure I’ve worked on so far, even larger than the flaps or ailerons.

Unlike those control surfaces, the stabilizer doesn’t move, so it lacks hinge assemblies. Still, assembling it was no small feat. The fit between the pre-drilled skins and internal ribs required finesse—minor misalignments meant a lot of careful drilling, deburring, and test fitting.

And then came the riveting marathon: hundreds upon hundreds of flush and domed rivets of various sizes, each demanding a perfect finish. It’s tedious but oddly meditative work, and you can really appreciate how every rivet contributes to strength and precision.

Bonus: Teen Pilot Down Under

During my visit, I met Lachlan “Lockie” Burns, the young Australian pilot behind Teen Pilot Down Under, who’s following in the footsteps of fellow Aussie circumnavigator Lachlan Smart—the Guinness World Record holder for being the youngest person to fly solo around the world in 2016. Lockie’s World Flight 2025 continues that legacy, aiming to inspire young people to chase their aviation dreams while promoting STEM education and the spirit of adventure. The Sling TSi he’s flying is outfitted with long-range tanks, an auxiliary fuel system, and dual Garmin G3X displays—basically a miniature global cruiser.

When I stopped by, the Airplane Factory maintenance team was performing a 100-hour inspection before his next leg. Seeing that very same model of airplane (just like mine!) that had already crossed oceans and continents was surreal. It’s one thing to imagine your future Sling traveling far—but another entirely to see one doing it in real life.

Next Steps

The next few weeks will be all about finishing the empennage, wrapping up firewall-forward, and finalizing the fuselage—a phase that should take about two to three weeks.

After that comes painting (roughly another month) and then we’ll enter the Finishing & Rigging phase. That’s when the avionics, upholstery, and interior all come together—and yes, when the engine start finally happens.

Once everything is buttoned up, the DAR will perform the official inspection, and we’ll be ready to move into Phase 1 flight testing.

Leave a comment