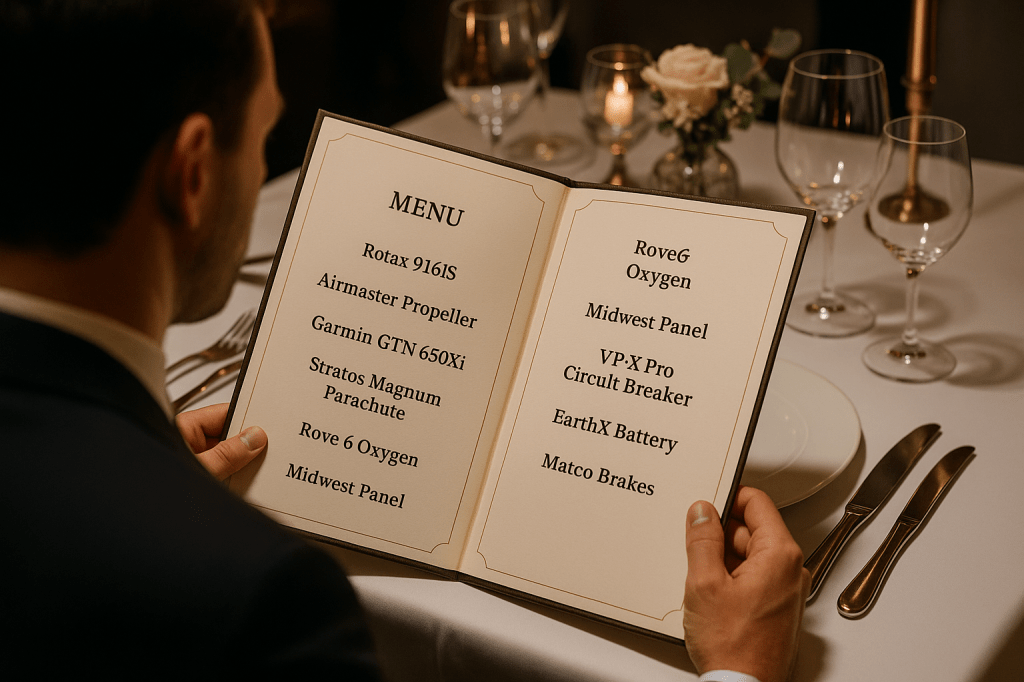

After nearly a year of research, conversations, spreadsheets, and the occasional late-night rabbit hole, it’s finally time to lock everything in. As the airplane transitions into the paint phase, every configuration choice—from engine to avionics, from parachute to visors—has been (hopefully!) finalized.

This post serves as a consolidated reference of all the major and minor configuration decisions for N117ZS. Most of these choices have been discussed in detail in earlier posts, which are linked throughout. A few new ones are included here for completeness.

Each section lists the final decision, summarizes the reasoning behind it, and—where applicable—notes any evolution from the original plan. The goal is to create a one-stop configuration reference, essentially a “build spec sheet” for the entire aircraft.

Table of Content

- Engine

- Propeller

- Electrical System

- Avionics

- Instrument Panel

- Airframe & Safety Systems

- Minor Systems & Accessories

- Configuration Summary Table

Engine

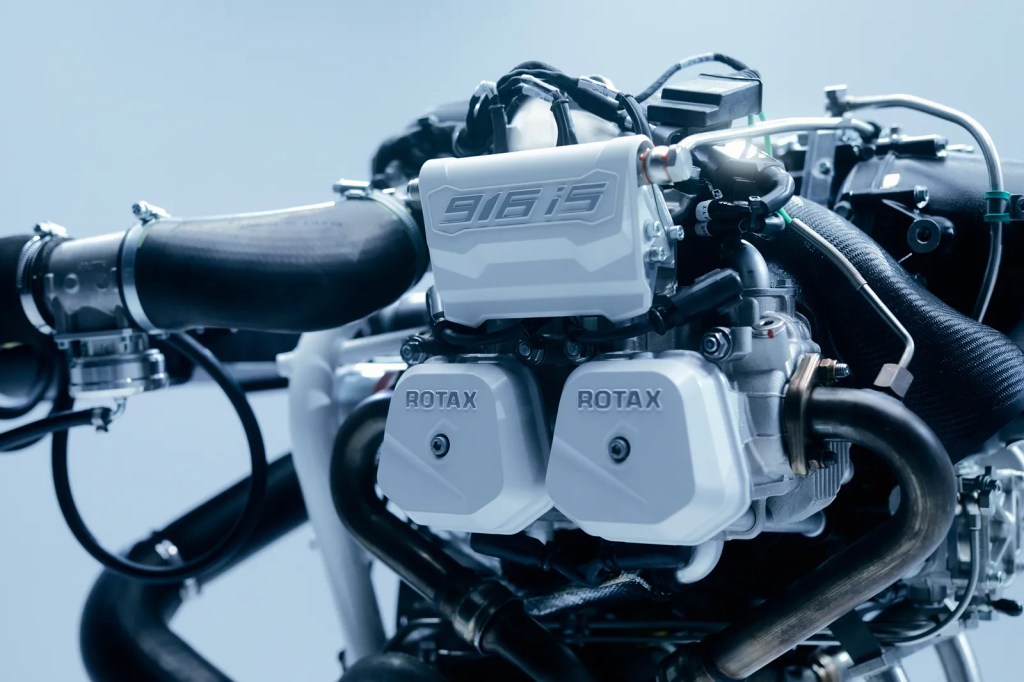

Final Decision: Rotax 916iS

Summary of Rationale:

The Rotax 916iS was selected as the powerplant for N117ZS. It represents the latest generation in Rotax’s turbocharged, FADEC-controlled line and delivers 160 hp, a 13% increase over the 915iS, with virtually no change in weight or installation requirements.

A major advancement—and a key factor in the decision—is the Time Between Overhaul (TBO), which has been extended to 2,000 hours (up from 1,200 hours on the 915iS). This improvement substantially reduces lifecycle cost and reflects the engine’s proven reliability and durability in operational service.

In addition to its higher output and longer TBO, the 916iS demonstrates improved cooling efficiency and slightly lower specific fuel consumption at cruise power settings. It integrates seamlessly with the Sling TSi airframe and retains full support from The Airplane Factory and Rotax for installation, maintenance, and parts.

Dubbed by Rotax as the “impossible engine,” the 916iS embodies the level of modernity, efficiency, and technology integration that defines this aircraft build. Its advanced electronic engine management, low fuel burn, and high power-to-weight ratio align perfectly with the project’s mission: to create a next-generation, capable, and efficient cross-country aircraft using state-of-the-art systems throughout.

The 916iS was the intended choice from the start, requiring no deviation from the original configuration.

Reference:

For detailed analysis of the 915iS vs. 916iS, including performance metrics and lifecycle cost considerations, see:

Propeller

Final Decision: Airmaster AP431HCTF Electric Constant-Speed Propeller with Whirlwind Blades (3-Blade Configuration)

Summary of Rationale:

The aircraft will use the Airmaster AP431HCTF electric constant-speed propeller paired with Whirlwind composite blades in a 3-blade configuration. This choice followed a comprehensive evaluation of propeller control systems (electric vs. hydraulic) and blade count performance (3 vs. 4 blades).

The Airmaster system was selected for its digitally controlled pitch mechanism, which replaces the traditional hydraulic governor, eliminating oil lines and reducing firewall-forward complexity. The electric hub provides four pre-programmed operating modes—Takeoff, Climb, Cruise, and Feather—allowing consistent, optimized propeller pitch control with minimal pilot workload.

The Airmaster AP431HCTF also provides advantages in maintenance and supportability. The system avoids oil-related servicing, reduces potential leak points, and simplifies hub inspections. It is approximately 8–10 lbs lighter than the MT hydraulic alternative, with modular components that facilitate field servicing and future blade replacements.

References:

For detailed discussions and comparative analyses, see:

- MT Hydraulic vs. Airmaster Electric Prop — The Push for a Truly Modern Sling TSi

- Blades of Glory — 3 vs. 4 on the Sling TSi

- Airmaster It Is — The Propeller Decision for My Sling TSi

Electrical System

External Alternator

Final Decision: Installation of an External Alternator

Summary of Rationale:

The Sling TSi equipped with the Rotax 916iS already includes dual internal alternators (GEN A and GEN B) providing 30A and 18A respectively. However, an additional external alternatorwas selected to provide a third, independent source of electrical power.

The key motivation for this choice was operational redundancy and load management. While the internal alternators are sufficient for standard VFR configurations, the chosen avionics and safety equipment suite (including dual G3X displays, GTN 650Xi navigator, GFC 507 autopilot, and other electrical loads) benefit from additional capacity and isolation. The external alternator supplies power directly to the main bus, supplementing the internal systems and reducing current draw on GEN A.

This configuration enhances system resilience during electrical faults. In the event of a GEN A or GEN B failure, the external alternator can maintain full avionics and essential systems operation without switching to battery-only mode. The system also allows independent shutdown of the Rotax alternators if a voltage anomaly or regulator issue arises, preserving aircraft power continuity.

Although the Rotax 916iS internal alternators are highly reliable, adding an external unit offers measurable operational advantages for IFR and cross-country use, where extended endurance and system redundancy are priorities.

Reference:

For an in-depth analysis of the design trade-offs, installation considerations, and redundancy benefits, see:

Circuit Protection

Final Decision: Vertical Power VP-X Pro Electronic Circuit Breaker System

Summary of Rationale:

The aircraft uses the Vertical Power VP-X Pro, an electronic circuit protection and power distribution system that replaces traditional mechanical circuit breakers. The VP-X integrates directly with the Garmin G3X avionics suite, allowing real-time monitoring, configuration, and fault reporting through the displays.

The primary motivation for this choice was system integration, weight savings, and in-flight situational awareness. The VP-X simplifies wiring by centralizing circuit control, provides digital load monitoring for each bus, and supports advanced features such as trim and flap position control, electronic load shedding, and programmable power sequencing.

A key consideration during evaluation was single-point-of-failure risk—the possibility of a VP-X hardware failure disabling multiple circuits. This concern was addressed by ensuring redundancy through independent essential circuits (e.g., engine ECU, ignition, and fuel pumps remain outside the VP-X system), in line with Sling TSi and Rotax installation best practices. The VP-X therefore manages only the avionics and secondary systems, leaving all critical engine functions powered directly from independent buses.

The result is a hybrid architecture: modern digital power management with the safety of conventional redundancy. This setup reduces panel clutter, streamlines maintenance, and improves diagnostic capability compared to traditional circuit breakers.

Reference:

For the full discussion on decision trade-offs, integration details, and risk mitigation strategies, see:

Battery

Final Decision: EarthX ETX900 Lithium Iron Phosphate (LiFePO₄) Battery

Summary of Rationale:

The EarthX ETX900 was selected for its high cranking performance, built-in battery management system (BMS), and significant weight savings over lead-acid alternatives. The LiFePO₄ chemistry provides excellent thermal stability and safety, addressing earlier lithium concerns while delivering stable voltage under high load.

At roughly 10 lbs lighter than a comparable AGM battery, the ETX900 supports both main and essential buses through the VP-X Pro, offering strong redundancy and simplified maintenance. EarthX’s proven reliability in Rotax installations and the clear performance benefits over legacy designs made it the preferred choice.

Reference:

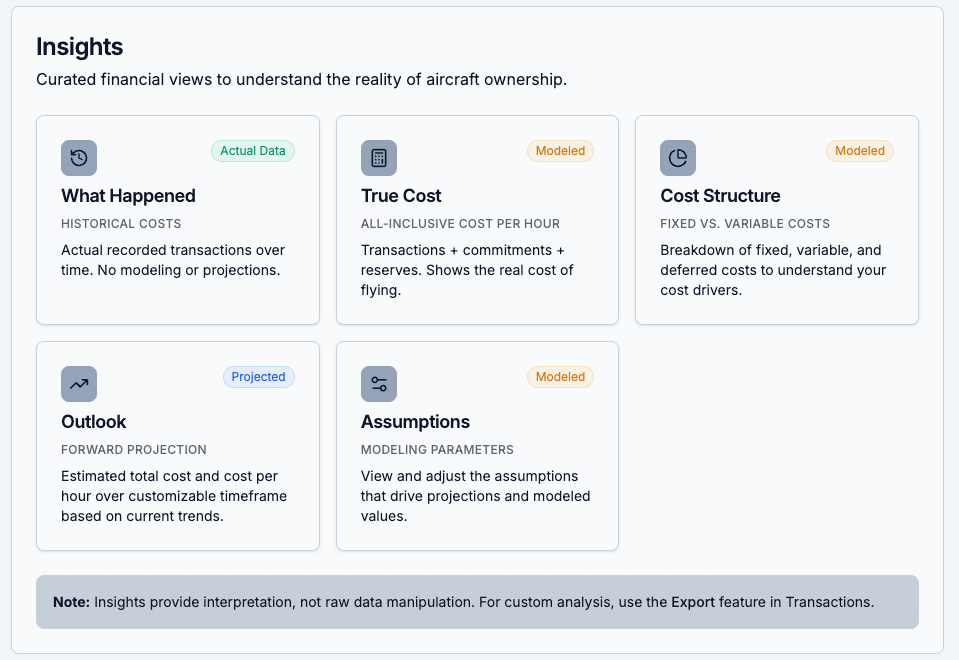

Avionics

Final Decision: IFR Garmin Integrated Avionics Suite

Summary of Rationale:

The avionics configuration for N117ZS centers on a fully integrated Garmin IFR suite, chosen for its system-level integration, reliability, and long-term support ecosystem. The setup includes dual G3X Touch displays as the core of the flight deck, a GTN 650Xi GPS/NAV/COM for IFR navigation and communication, and the GFC 507 autopilot for precise, envelope-protected flight control.

The Garmin ecosystem was selected to ensure tight integration across all flight, navigation, and communication functions, reducing workload and enhancing situational awareness. System elements such as the G5 backup instrument, GMA 245R remote audio panel, and GTX 45R transponder provide redundancy and compliance with IFR and ADS-B requirements.

Garmin’s software maturity, unified interface design, and service network were also important selection factors. The result is a modern, IFR-capable flight deck optimized for operational simplicity, redundancy, and future expandability.

Avionics Configuration Summary

| Component | Function / Description | Notes |

|---|---|---|

| Garmin G3X Touch (Dual Displays) | Primary Flight Display (PFD) and Multi-Function Display (MFD) | Core integrated flight and engine instrumentation |

| Garmin GTN 650Xi | IFR GPS/NAV/COM | Certified navigator for enroute, approach, and communication; primary IFR source |

| Garmin GFC 507 Autopilot | Digital 2-axis autopilot with electric trim | Full integration with G3X and GTN for coupled approaches and envelope protection |

| Garmin G5 Backup Display | Independent standby flight instrument | Backup attitude, airspeed, and altitude data |

| Garmin GTR 205XR COM Radio | Secondary VHF communication | Integrated with G3X touchscreen interface |

| Garmin GMA 245R Audio Panel | Remote-mounted digital audio panel | Provides intercom, Bluetooth, and audio mixing via G3X |

| Garmin GTX 45R Transponder | ADS-B Out / In | Remote-mounted, controlled through G3X |

| Garmin GHA 15 Radar Altimeter | Height-above-terrain measurement | Integrated callouts and display on G3X |

| Garmin GCO 14 CO Detector | Carbon monoxide sensor | Real-time CO monitoring with alert integration |

| Garmin LEMO Headset Jacks (2x) | Power and audio interface for ANR headsets | Installed for pilot and copilot positions |

| 12V Accessory Port | Power outlet | For portable equipment, e.g., oxygen system |

| Dual USB Ports | Charging and data | Supports EFB and portable device connectivity |

References:

For detailed analysis of each component and design integration, see:

- Inside the Panel — My Garmin-Powered Sling TSi Avionics Suite

- From Concept to Cockpit — Finalizing My Sling’s Avionics Panel

Instrument Panel

Final Decision: Custom-Configured Midwest Panel Builders Layout (Garmin-Based, Partial Backlight Panel)

Summary of Rationale:

The instrument panel is based on the standard Midwest Panel Builders design for the Sling TSi, modified to incorporate the aircraft’s specific power architecture and equipment configuration, including integration of the Airmaster propeller controller and custom electrical interfaces.

The panel layout maintains the dual Garmin G3X Touch displays as the central focus, with the GTN 650Xi, GFC 507 autopilot, and G5 backup instrument positioned for ergonomic access and system redundancy. Control grouping and labeling follow a logical left-to-right sequence aligned with flight operations, providing clear workflow and intuitive use.

A backlight panel was selected for improved nighttime readability and professional appearance. However, the earlier partial backlight version was chosen instead of the latest full-backlight panel offered by Midwest, balancing functionality and aesthetics with cost efficiency.

These adjustments preserve the proven reliability of the Midwest baseline design while ensuring the final configuration aligns with the aircraft’s custom electrical systems and operational requirements.

Reference:

Airframe & Safety Systems

Parachute System

Final Decision: Stratus 07 Magnum 901 Whole-Airframe Parachute System (BRS-Compatible Installation)

Summary of Rationale:

The aircraft will be equipped with the Stratus 07 Magnum whole-airframe parachute system. This unit, supplied and supported through The Airplane Factory, is the approved parachute option for the Sling TSi. It operates similarly to the Ballistic Recovery Systems (BRS) design, using a rocket-deployed canopy to recover the entire aircraft and occupants in the event of unrecoverable flight conditions.

The decision to include a parachute was made early in the configuration process as a primary safety feature, not an optional accessory. While the system adds approximately 50 lbs and a meaningful cost increase, it provides a significant improvement in overall safety margins—particularly for engine failures, night IFR operations, or flight over mountainous terrain or water.

Selecting the Magnum system aligns with the build’s overall philosophy of modern capability with embedded redundancy and survivability. The integration was planned from the outset to ensure proper structural mounting and load path alignment within the fuselage assembly.

Reference:

Oxygen System

Final Decision: Inogen Rove 6 Portable Oxygen Concentrator

Summary of Rationale:

The aircraft will carry the Inogen Rove 6, a portable oxygen concentrator that produces oxygen on demand rather than storing it in a pressurized cylinder. This decision was made after evaluating several alternatives—including the Aithre AVI24 Smart Pulse and Turbo Oxygen Maker—and determining that the Inogen offered the best combination of simplicity, safety, and operational flexibility.

The Rove 6 requires no refilling, eliminates bottle logistics, and supports both pulse and continuous flow modes. It can operate from the aircraft’s 12V outlet and provides sufficient flow for two occupants at typical cruise altitudes up to 15,000 feet. The system is FAA-approved for in-flight use and can be easily removed from the aircraft when not needed, minimizing installed weight.

Compared to built-in or semi-permanent oxygen systems, the Inogen solution aligns with the overall design philosophy of low-maintenance, lightweight, and portable systems that enhance usability without adding complexity to the build.

Reference:

Brakes

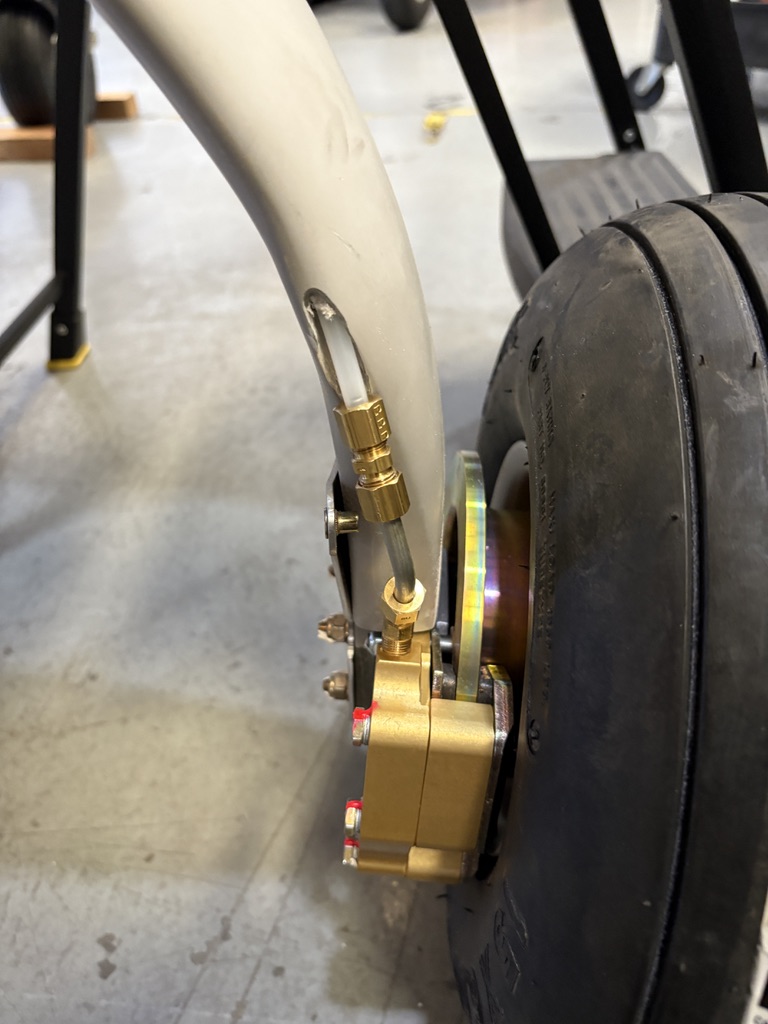

Final Decision: Updated Matco Dual-Caliper Brake System (Standard Sling TSi Configuration)

Summary of Rationale:

The aircraft uses the standard Matco brake system, upgraded to the dual-caliper configuration now offered on the Sling TSi. This setup provides improved braking authority and heat dissipation while maintaining full compatibility with the existing wheels and landing gear geometry.

The decision to stay with Matco, rather than upgrade to the Beringer system, was based on cost-benefit analysis, serviceability, and fleet experience. The Beringer option offered minor advantages in pedal feel and weight but at a substantial cost increase and with added complexity in parts sourcing.

The Matco dual-caliper system delivers reliable stopping performance, simplified maintenance, and broad availability of replacement components. It represents a practical and proven solution consistent with the aircraft’s operational intent—primarily long cross-country and IFR missions rather than high-cycle or short-field operations.

Reference:

Boost Fuel Pumps

Final Decision: Deferred Installation — No Auxiliary Boost Pumps Installed at This Time

Summary of Rationale:

The initial plan included installation of the Aerospace Innovations auxiliary wing-mounted fuel pumps, designed to supplement the standard dual Rotax pumps and provide additional protection against vapor lock, especially when operating on MOGAS in hot or high-density-altitude conditions.

These pumps were attractive for their redundancy and fuel pressure stability, and several builders reported good early results. However, after a recall affecting the internal check valves and subsequent discussions with the manufacturer, concerns arose regarding long-term reliability and the complexity of servicing the pumps once installed inside the wings—since any future replacement would require wing removal.

Given the early stage of field experience with this system and the potential service challenges, the decision was made to defer installation. The aircraft retains the standard dual Rotax pumps, which provide full redundancy for normal and backup operation, while keeping the option open to revisit the auxiliary system once more long-term reliability data are available from other Sling installations.

Reference:

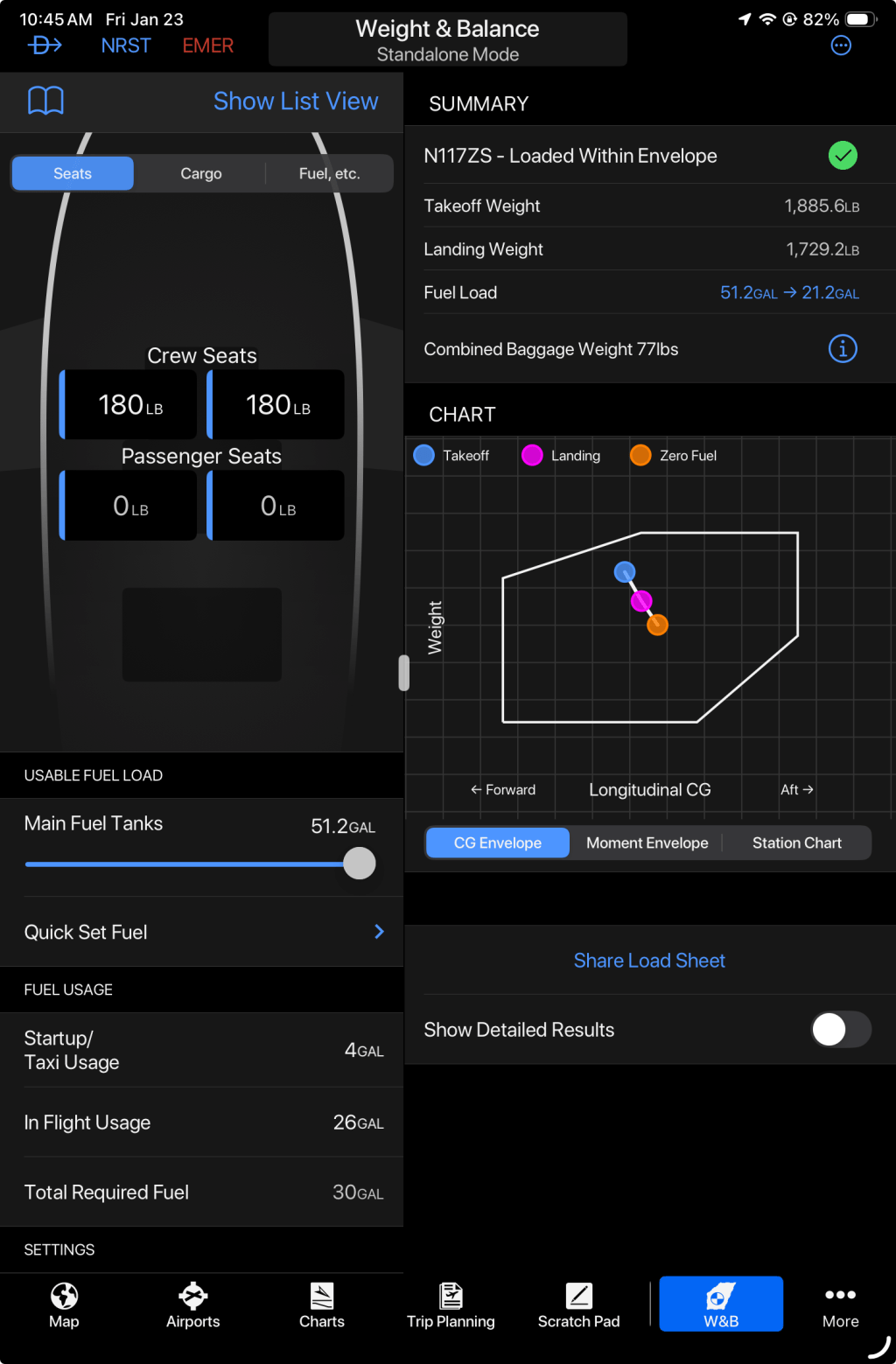

Long-Range Fuel Tanks

Final Decision: Standard 52-Gallon Tanks Only — Long-Range Option Not Installed

Summary of Rationale:

The Sling TSi offers an optional long-range fuel system that adds 22 gallons of additional capacity (11 gallons per wing), bringing total usable fuel to approximately 74 gallons. The modification extends endurance by several hours but requires additional fuel lines, selector valves, and management of four separate tanks instead of two.

After evaluation, the decision was made not to include the long-range tanks. The standard 52-gallon configuration already provides ample range—typically exceeding 800 nautical miles with reserves—which aligns well with the aircraft’s cross-country mission profile. In practice, remaining in the cockpit for more than four to five hours without a break would be impractical and uncomfortable, limiting the operational value of the extended range.

The long-range system also adds complexity, weight, and potential failure points while reducing available payload for baggage or passengers. For these reasons, the standard fuel system was deemed the simpler, lighter, and more operationally practical choice, offering a balanced compromise between endurance and efficiency.

Minor Systems & Accessories

Rosen Sun Visors

Final Decision: Slap-on Canopy Visors (Rosen Visors Not Selected)

Summary of Rationale:

The Rosen sun visor kit was evaluated but not selected due to visibility limitations created by the Sling TSi’s canopy shape. During transition training at The Airplane Factory’s Sling Academy, the visors were found to impair forward visibility.

Feedback from other Sling owners confirmed the issue, with several removing the visors after installation. Instead, simple slap-on canopy visors will be used as needed. This approach maintains clear sightlines, adds no weight or complexity, and avoids cockpit clutter.

Fuel Quantity System

Final Decision: Standard Sling Float-Type Fuel Senders (CiES Not Selected)

Summary of Rationale:

While the CiES digital fuel senders were considered for their higher precision and Garmin integration, they were not selected. Although the CiES units provide smoother digital readings, they do not improve accuracy, particularly since neither the factory nor CiES senders can measure fuel above approximately 16 gallons per tank—requiring manual verification during preflight.

Because the fuel totalizer in the Garmin system provides an accurate record of fuel consumption once initialized with the correct starting quantity, the additional precision of the CiES sensors was not seen as offering practical benefit.

The decision avoids added complexity, cost, and potential installation issues, while relying on established and proven methods: manual measurement before flight and totalizer-based tracking in flight.

Configuration Summary Table

The following table consolidates all key configuration decisions for N117ZS, organized by system category. Each decision reflects the final selections made before the aircraft entered the paint phase.

| Category | Decision / Configuration | Notes / Rationale Summary |

|---|---|---|

| Engine | Rotax 916iS (160 hp) | Latest-generation FADEC turbo engine offering improved climb and high-altitude performance with minimal weight change. |

| Propeller | Airmaster AP431HCTF (3-blade Whirlwind) | Electric constant-speed system; lighter, simpler, and more modern than hydraulic alternatives. |

| Electrical — External Alternator | B&C BC462-H | Adds third independent power source for redundancy and load management. |

| Electrical — Circuit Protection | Vertical Power VP-X Pro | Electronic circuit breaker system integrated with Garmin G3X; hybrid redundancy architecture. |

| Electrical — Battery | EarthX ETX900 LiFePO₄ | Lightweight lithium battery with integrated BMS; ~10 lbs lighter than AGM equivalent. |

| Avionics Suite | Garmin Integrated System | Dual G3X Touch, GTN 650Xi, GFC 507 autopilot, G5 backup, GTX 45R, GMA 245R, GTR 205XR, GHA 15 radar altimeter, CO detector, LEMO jacks, USB & 12V ports. |

| Instrument Panel | Midwest Panels Custom (Partial Backlight) | Based on standard Sling layout with modifications for power architecture and Airmaster controller; partial backlight version selected for cost efficiency. |

| Parachute System | Magnum 601 Whole-Airframe Parachute | Adds ~50 lbs; key safety feature for emergency recovery; factory-supported installation. |

| Oxygen System | Inogen Rove 6 Portable Concentrator | Lightweight, refill-free system powered from aircraft 12V; supports two occupants up to 15,000 ft. |

| Auxiliary Fuel Pumps | Deferred — Aerospace Innovations Pumps | Initially planned for vapor-lock mitigation; deferred due to recall, reliability, and maintenance concerns. |

| Brakes | Matco Dual-Caliper System | Standard configuration with dual-caliper upgrade for improved braking power and heat management. |

| Fuel Tanks | Standard 52-Gallon Configuration | Long-range (74-gallon) option omitted to avoid added complexity, weight, and management workload. |

With the aircraft now entering the paint phase, these selections represent the finalized configuration for N117ZS. Each choice reflects a balance between performance, reliability, maintainability, and mission practicality—guided by both technical analysis and real-world operational considerations.

Leave a comment